Batteries Series and parallel is the act of connecting two or more batteries together, by connecting the two or more battery in either series and parallel, you can increase the capacity, voltage, ultimately allowing for more power and/or energy, then the equipment will last longer. Before study the wiring difference between the batteries in series and parallel, we need to know how to wire the battery in series and parallel. And What is does exactly mean of these terms mean.

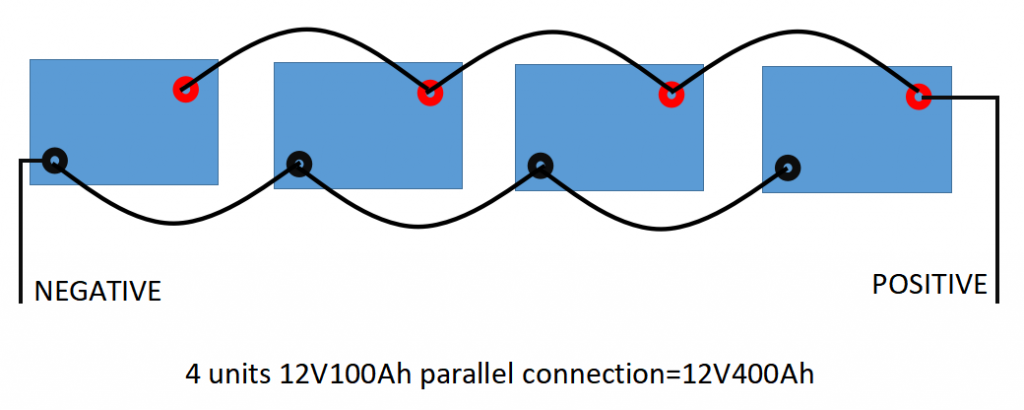

parallel connection

The battery capacity will be increased, the voltage will be keep not change, and internal resistance will be reduced.

Lithium battery Parallell connection always ivolve connecting 2 or more batteries together to increase the amp-hour capacity of the battery bank, but your voltage stays the same. To connect batteries in parallel, the positive terminals are connected together via a cable and the negative terminals are connected together with another cable until you reach your desired capacity.

Below example is four 100 Ah batteries wired in parallel. The negative terminal on the first battery is connected to the negative terminal on the second. Likewise, the positive terminals of both batteries are also connected. The total system voltage is 12 volts, and the total capacity is 400 Ah.

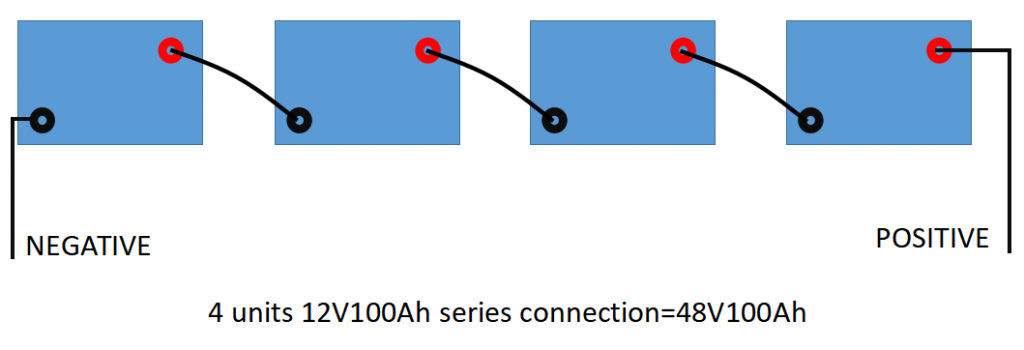

Series connection

The battery voltage will be increased, the capacity will be keep not change, and internal resistance will be increased.

Lithium battery series connection always involve connecting 2 or more batteries together to increase the voltage of the battery system but keeps the same amp-hour rating. Before connection, pls Keep in mind in series connections each battery needs to have the same voltage and capacity rating, or you can end up damaging the battery. To connect batteries in series, you connect the positive terminal of one battery to the negative of another until the desired voltage is achieved. When charging batteries in series, you need to utilize a charger that matches the system voltage. We recommend you charge each battery individually, with a multi-bank charger, to avoid an imbalance between batteries.

Below example is four 100 Ah 12Volts batteries wired in series. As you can see, the positive terminal on the first battery is connected to the negative terminal on the second. Thus, the total system voltage is 48 volts, and the total capacity is 100 Ah.

Nearly all lithium batteries are packed through battery cells, just like every organ of our body is composed of cells, the battery internal structure are connect in series and parallel before our factory install whole battery pack into the case, The 300Ah 12.8Volts LiFePO4 lithium battery are packed through 4S3P, which means 4 units 3.2V100Ah LiFePO4 battery cell in series connection and 3units 3.2V100Ah LiFePO4 battery cell in parallel connection, then the whole battery become 300Ah 12.8Volts LiFePO4 battery. However, that is not enough at all because many system is 36V, 48V, 72V system even for golf carts , saitboat etcs, So there are must the problem what is the wiring difference between batteries In Series Vs Parallel Connection?

Notices before wiring batteries up in series or parallel

- Do not wiring the batteries with different chemistries, For example, don’t attempt to connect SLA batteries with LiFePO4 batteries in series or parallel. Whichever battery quits first (in this instance, it will likely be the SLA battery that dies first) will weigh down the performance of the other(s), and thus give you less use time. If one were to keep using this mix-and-match setup, both batteries would eventually become so unbalanced (more on cell balancing below) that they will essentially become unusable.

- Do not wiring different brands of lithium iron phosphate lithium ion battery packs, different capacities or new and old lithium ion batteries, and choose batteries with the same performance. When the battery power is low, replace all the batteries. When using lithium-ion battery packs in series, use the same type of battery. Pay attention to the polarity of the battery. If the polarity of one battery is installed reversely, the voltage of the entire string of batteries will be reduced instead of adding a new voltage.

- Do not wiring new lithium battery with old batery, there may be leakage, zero voltage and other phenomena. This is because during the charging process, the capacity difference causes some batteries to be overcharged and some batteries are not fully charged. During discharging, some batteries with high capacity are not fully discharged, and batteries with low capacity are over-discharged. In such a vicious circle, the battery is damaged and leaks or low (zero) voltage.

- General lithium iron phosphate battery packs are used in series and parallel to match lithium ion battery cores. The pairing standard: lithium ion battery core voltage difference ≤10mV, lithium ion battery core internal resistance difference ≤5m, lithium ion battery core capacity difference ≤20mA .

- It’s also best to use batteries that are identical in voltage and amp hour specs. The easiest way to do this is to simply wire up two (or more) models of the same battery (Like our Keheng KH-LFP-SC-12100B series capable Lithium 12V 100Ah batteries). Things can get tricky if you’re wiring up batteries that have different battery management system electronics in them, and the permutations for what can happen are fairly wide. Regardless of the differences in those outcomes, you’ll often still end up with wildly unbalanced cells, as in the previous point.

- How to charge battery in series VS parallel?

Charging Lithium Batteries In Series

At present, lithium battery tends to be charged in series, which is mainly due to its simple structure, low cost and easy realization. But as a result of different capacity, internal impedance, aging characteristics and self-discharge performance, when charge lithium battery in series, battery cell with the smallest capacity will be fully charged first, and at this point, the other battery cell is not full of electricity. If continue to charge in series, the fully charged battery cell may be overcharge.

Lithium Battery overcharge will damage the battery performance, and even lead to explosion and injuries, therefore, to prevent battery cell overcharging, lithium battery has equipped with Battery Management System (BMS). The Battery Management System has overcharge protection for every single lithium battery cell, etc. When charging in series, if the voltage of a single lithium battery cell reaches the overcharge protection voltage, the battery management system will cut off the whole series charging circuit and stop charging to prevent the single lithium battery cell from being overcharged, which will cause other lithium batteries unable to be fully charged.

Charging Lithium Batteries In Parallel

In parallel charging of lithium batteries, each lithium ion battery needs equalizing charge, otherwise, the performance and life of the whole lithium ion battery pack will be affected. Common charging equalization technologies include: constant shunt resistance equalizing charge, on-off shunt resistance equalizing charge, average battery voltage equalizing charge, switch capacitor equalizing charge, step-down converter equalizing charge, inductance equalizing charge, etc.

After lithium ion batteries connecting in parallel, there will be a charging protection chip for lithium battery charging protection. Lithium battery manufacturers have fully considered the change characteristics of lithium battery in parallel before battery production. The above requirement of current design and choice of batteries are very important, so that users need to follow the instructions of parallel lithium batteries charging step by step, so as to avoid the possible damage for incorrect charge.

Can keheng batteries be connected in series and parallel?

To support the batteries parallel or series connection, the durable current and voltage of BMS and battery need to be increased, for example, if we connnect the 4 units 12.8V100Ah LiFePO4 batteries in series, the system will be 51.2V100Ah system, the durable voltage and voltage typically need to be increased, that is will increased the cost abviously, in order to reach the different application with most favorable price, we typically recommend a maximum of 4 batteries in parallel for our standard product. To reach the 48V or higher voltage system, we design KH -LFP-SC series(Series capable battery series) to realize the function. For more requirement, such as 60V, 72V system, We keheng can provide the unique design according to the system requirement of appliance. reach keheng team for customized requirement.

Addition question that you may ask about the battery in series and parallel.

- Where I can buy the series capable LiFePO4 battery? Cleck here to buy and know more parameter about the LiFePo4 lithium battery.

- Can your battery be connect to 72V, 96V high voltage? Yes, but the battery need to customized since it is not common, cleck here to connect with keheng team and get customized battery.

- Did all of your battery support parallel connection?Yes, all of the battery are support 16units parallel connection maxium.