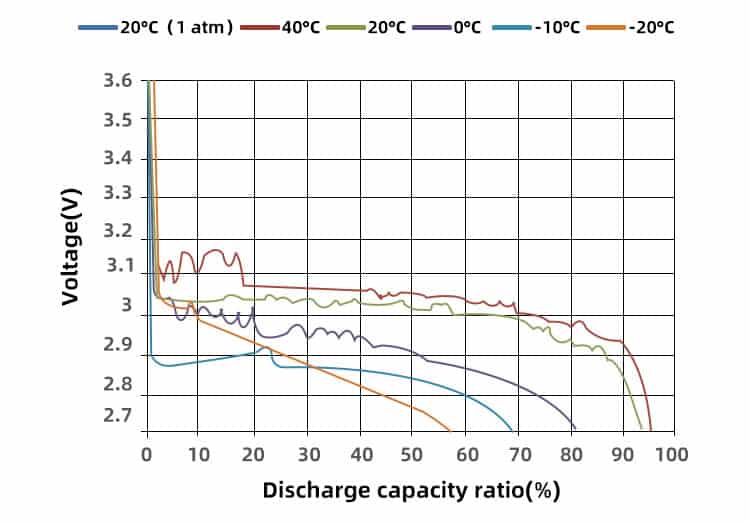

This 10Ah 12V LiFePO4 series connection capable battery packs a big punch in a small package. Engineered in a 10Ah SLA case, but with 10Ah of Lithium Iron Phosphate (LiFePO4) technology, this battery has half the weight, and lasts 2 times longer than a normal 10Ah sealed lead acid battery – providing exceptional performance & lifetime value. Optimal performance down to minus 20 degrees Fahrenheit (for winter warriors).

10 Amp hours of capacity provides a full day of power for high amp draw electronics like Garmin fish finders, ice augers, or anything where you need a longer run time. Drop in replacement for 10Ah SLA batteries (same size, physical dimensions & terminals).

Combine 2 for 24 Volts or 4 for a 48 Volt system. ideal for industrial purposes where you need a long lifespan battery that charges quickly, or for outdoor uses like hiking or camping where weight is at a premium.

Best Waterproof Battery Case Waterproof Battery

This 12 Volt Waterproof Battery Pack is great for boating, kayaking, … Features a rugged, water-resistant case and a rechargeable 12-volt battery.

12v 10ah LiFepo4 Lithium Ion Battery Energy Ratio

12v 10ah LiFepo4 lithium ion battery is a high energy ratio battery,Energy density is the measure of how much energy a battery contains in proportion to its weight. This measurement is typically presented in Watt ..

The weight is 0.98KG, and the energy is up to 128WH, which is twice that of the lead-acid battery.

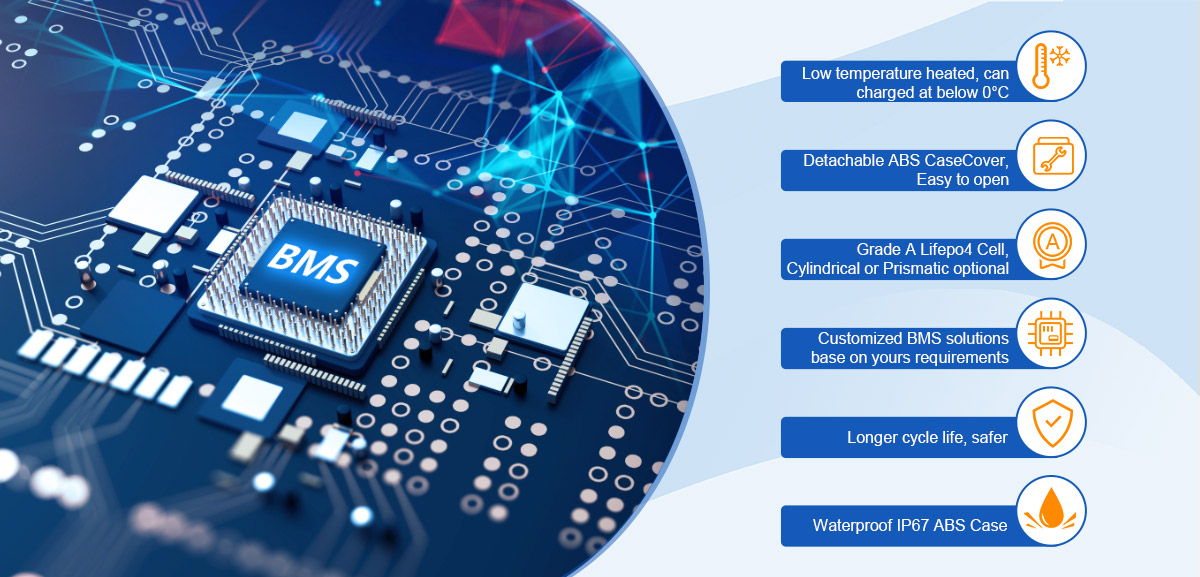

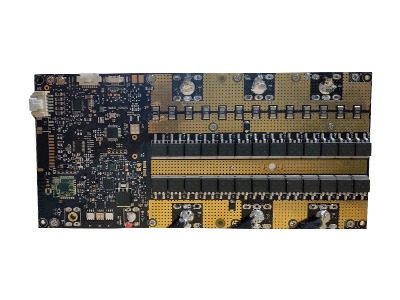

10AH 12V LiFePO4 series Battery BMS

Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically organized in a row x column matrix configuration to enable delivery of targeted range of voltage and current for a duration of time against expected load scenarios. The oversight that a BMS provides usually includes:

- Monitoring the battery

- Providing battery protection

- Estimating the battery’s operational state

- Continually optimizing battery performance

- Reporting operational status to external devices

Battery management systems do not have a fixed or unique set of criteria that must be adopted. The technology design scope and implemented features generally correlate with:

- The costs, complexity, and size of the battery pack

- Application of the battery and any safety, lifespan, and warranty concerns

- Certification requirements from various government regulations where costs and penalties are paramount if inadequate functional safety measures are in place

Monitoring battery pack current and cell or module voltages is the road to electrical protection. The electrical SOA of any battery cell is bound by current and voltage. Figure 1 illustrates a typical lithium-ion cell SOA, and a well-designed BMS will protect the pack by preventing operation outside the manufacturer’s cell ratings. In many cases, further derating may be applied to reside within the SOA safe zone in the interest of promoting further battery lifespan.

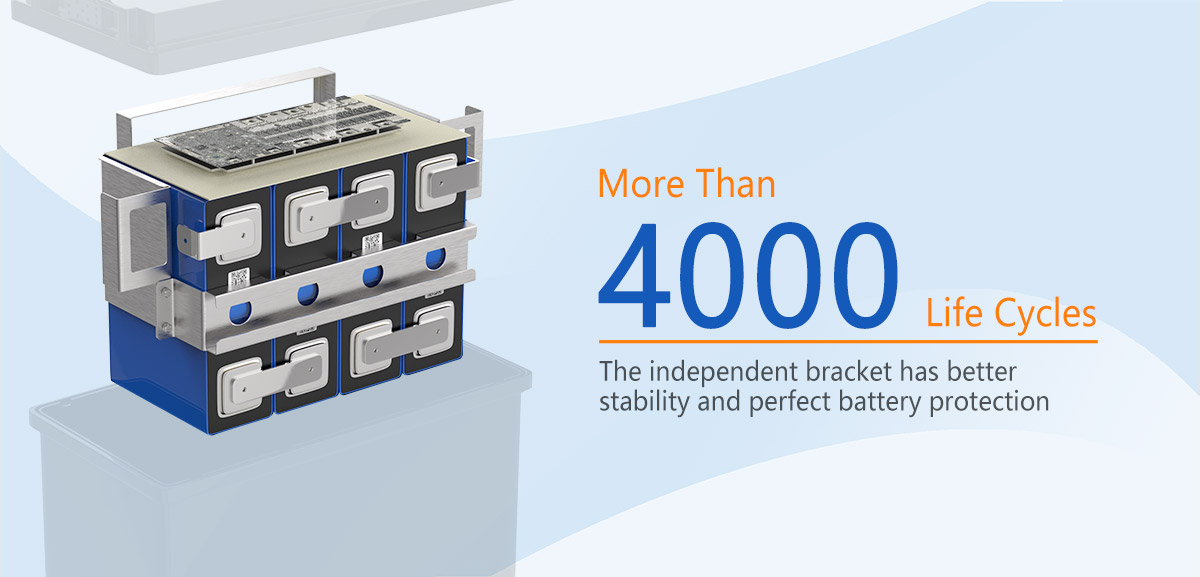

Fixing Of Battery Cells And Battery Box

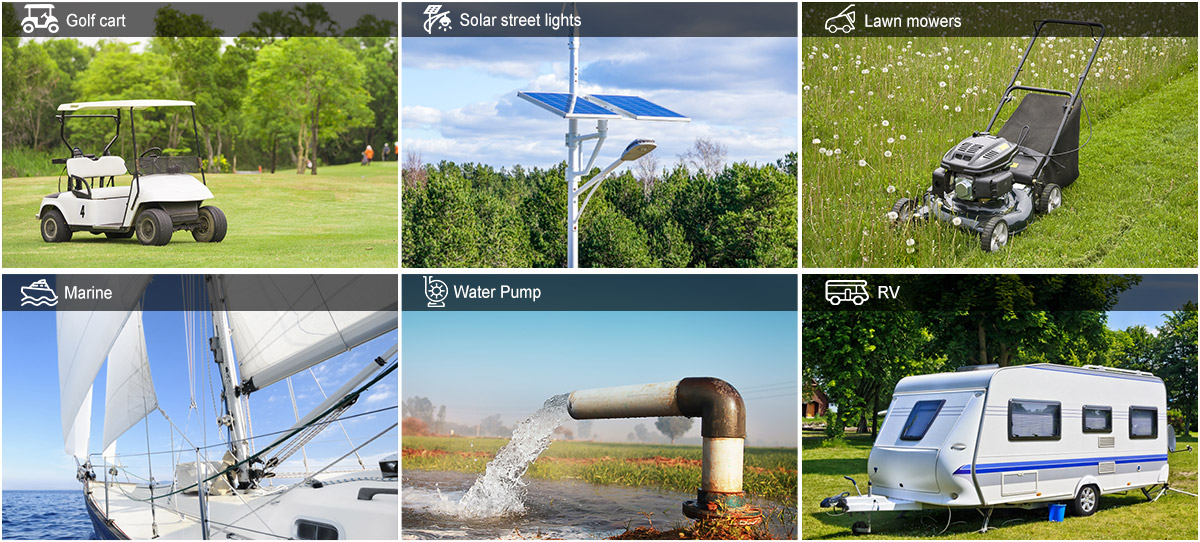

10AH 12V LiFePO4 series Battery Applications

- Solar/wind Energy storage system

- Golf carts

- Recreational Vehicles(RVs)

- Marine machine

- UPS Backup power system

- Solar street light

10AH 12V LiFePO4 series Batteries In Series And Parallel

The main difference in wiring batteries in series vs. parallel is the impact on the output voltage and the capacity of the battery system. Batteries wired in series will have their voltages added together. Batteries wired in parallel will have their capacities (measured in amp-hours) added together.