Phased progress has been made in energy density solid-state lithium batteries. In terms of industrialization demonstration of high-energy-density, high-safety deep-sea solid-state lithium batteries, the company has conquered the key core technologies of deep-sea long-endurance power supplies, and has achieved the 11,000-meter pressure chamber test. And the whole deep-sea demonstration application, boosting the national deep-sea power supply to a new height.

The fire accidents of Tesla electric vehicles have occurred one after another, and several domestic accidents have been very serious, and even the whole vehicle has been severely burned, which makes people re-examine the safety of commercial lithium-ion batteries. The liquid organic electrolyte in traditional lithium-ion batteries is the main culprit for the hidden danger of combustion and explosion. Although the battery management system can ensure the consistency and safety of the battery to a certain extent, when a puncture is caused by an external force collision, it is inevitable that the lithium-ion battery will catch fire and explode. Obviously, this cannot be solved by purely external battery management or physical peripheral protection. It is necessary to theoretically break through the design concept of lithium batteries, thereby fundamentally improving the safety of lithium batteries.

The use of solid electrolytes to replace traditional liquid electrolytes is considered to be the only way to substantially improve the safety of lithium batteries. However, due to a series of scientific problems such as the compatibility of solid-solid interfaces that need to be solved urgently and the immature technology for large-scale preparation of solid electrolytes, there has been no commercialized solid-state lithium battery with high energy density. Relying on the Qingdao Institute of Bioenergy and Process Research, Chinese Academy of Sciences, the Qingdao Energy Storage Industry Technology Research Institute (abbreviation: Qingdao Energy Storage Institute), with the support of the Chinese Academy of Sciences Nano Project, after years of exploration and development, has achieved high energy density solid-state lithium batteries. It has made a series of progress in the field of basic research, and has published 42 SCI papers. In the industrialization demonstration of high-energy density, high-security deep-sea solid-state lithium batteries, it has conquered the key core technologies of deep-sea and long-endurance power supply. , has achieved the 11,000-meter pressure chamber test and the full-sea deep-sea demonstration application, boosting the national deep-sea power supply to a new height.

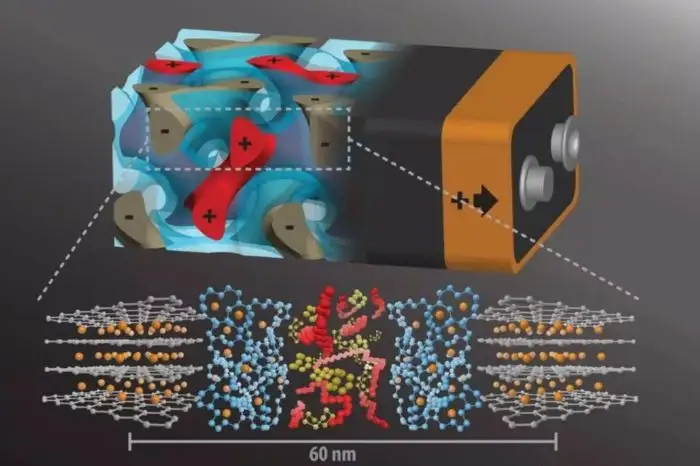

Solid-state electrolyte is the core component of solid-state lithium-ion battery. Research and development of solid-state electrolyte system with excellent comprehensive performance is the core and bottleneck of system to improve battery performance. However, regardless of inorganic materials or polymer materials, only a single material cannot meet the requirements for comprehensive performance improvement of large-capacity batteries such as ionic conductivity, mechanical strength, and thermal stability. In order to solve this problem, Qingdao Energy Storage Institute put forward the design concept of “rigid and flexible” solid-state polymer electrolyte, and made use of the advantages of different materials to innovatively composite “rigid” porous skeleton materials and “flexible” polymer ion transport materials. Through the complementary advantages of rigid and flexible materials, combined with the characteristics of Lewis acid-base interaction to increase block motion and improve interface ion transport, a variety of “rigid and flexible” solid polymer electrolytes with excellent comprehensive properties have been prepared to meet the requirements of long battery life, Strict requirements for high-safety solid-state lithium batteries. A series of results have been published in ACSAppl.Mater.Interfaces,2017,9,3694; Electrochim.Acta,2017,225,151; J.Mater.Chem.A,2016,4,5191; Chem.Mater.,2017,236,221; Appl. Mater.Interfaces,2017,9,8737;Adv.Sci.,2017,DOI:10.1002/advs.201700174;J.Mater.Chem.A,2017,5,11124 and other academic journals.

The ionic conduction at the solid-solid interface between the solid-state electrolyte and the electrode is related to the success or failure of solid-state lithium batteries. In order to effectively reduce the interface impedance, inspired by the “SEI film”, Qingdao Energy Storage Institute proposed an “in-situ self-formation” mechanism. First, liquid monomer molecules are infiltrated into the electrode interface, and then in-situ polymerized into a high-molecular-weight solid electrolyte. This “in-situ self-formation” system can effectively solve the ion conduction at the solid-solid interface, while improving the distribution of lithium ions at the interface to suppress lithium dendrites. The results were published in Adv.Sci., 2017, 4, 1600377; 2017, DOI: 10.1002 /manuscriptNo.advs.201700174. Based on this concept, the integrated solid-state sodium battery constructed by Qingdao Energy Storage Institute can effectively reduce the interface impedance and widen the electrochemical window, greatly improving the long-term cycle stability of the solid-state sodium battery. At the same time, the “in-situ self-formation” method is further extended to the application of high-voltage lithium iron manganese phosphate cathode and the in-situ protection of lithium metal anode. A series of results were published in Small, 2017, 13, 1601530; J.Mater.Chem. A. 2017, 5, 11124; Chem. Mater. 2017, 29, 4682.

In the practical application of solid-state batteries, extrusion, puncture and other phenomena are inevitable. How to deal with the consequent solid-solid interface failure problem is very necessary. Qingdao Energy Storage Institute cleverly used the temperature-responsive gelation process of thermally reversible polymers to construct a solid-state battery system with a “cooling recovery” function (Figure 2). After being strongly squeezed or folded, although the contact between the electrolyte and the electrode is destroyed and the battery performance plummets, an effective solid-solid interface can be reshaped by a simple low-temperature cooling step, and the battery performance can be recovered efficiently. The results were published in Angew Chem. Int. Ed. 2017, DOI: 10.1002/anie.201704373. In terms of large-capacity device integration and pilot testing of solid-state lithium batteries, Qingdao Energy Storage Institute has broken through the technical bottleneck of high-energy density solid-state lithium batteries: a large-capacity solid-state lithium battery has been successfully developed; the third-party testing energy density of the National Chemical Power Testing Center has reached 300Wh /kg, the cycle life is more than 500 times; and they further develop the polymer’s thermal flow to cut off the short-circuit point to ensure safety performance. Multiple nail penetration experiments show that the battery is extremely safe and has self-healing properties.

In March 2017, the “Qingneng-I” solid-state battery developed by the Qingdao Energy Storage Institute went to the Mariana Trench with the Chinese Academy of Sciences’ abyss scientific research team to provide energy for the control system and CCD sensor of the “Wanquan” lander, which was successfully completed. The 10,000-meter deep-sea demonstration application marks that the Chinese Academy of Sciences has broken through the technical bottleneck of the deep-sea power supply and mastered the core technology of the deep-sea power supply system. This technology will help develop the high performance and long battery life of the deep-sea submersible represented by the “Jiaolong”. Power system provides technical support. Relevant achievements and technologies have applied for 29 Chinese invention patents and 3 international PCT patents.

The above work is supported by the National Fund for Distinguished Young Scholars, the Nano-Special Project of the Chinese Academy of Sciences, the Deep-sea Power Project of the Chinese Academy of Sciences, the Shandong Province Forward-looking Special Fund and the Qingdao Energy Storage Institute Think Tank Joint Fund.