12 Tips to Choose the Lithium Battery Manufacturer

We participated in 8 lithium battery energy related exhibitions this year, every exhibition is very hot, more and more people and companies want to step into the lithium battery industry, while there are too many lithium battery suppliers on the market. Choosing the wrong lithium battery manufacturer will cause great losses, and may affect the end customers. As an old bird in the lithium battery industry for more than 15 years, when communicating with experienced sourcing manager and company owner, we often talked about what are the main factors when choosing a lithium battery manufacturer? Below is my summary of the 12 main considerations.

Table of contents

- 12 Tips to Choose the Lithium Battery Manufacturer

- 1, Experience in the lithium battery industry

- 2, Complete control of the battery cells supply chain

- 3, Continuous technical support

- 4, Production capacity

- 5, Update Technology–R&D

- 6, Compatibility with inverters & charger

- 7, Customization Service

- 8, Variety Of Product Line

- 9, Battery Certification

- 10, Mature technology & After-sales service

- 11, Sales support

- 12, Full inspection of all components–QC

1, Experience in the lithium battery industry

When it comes to a lithium battery manufacturer vendor, experience makes the difference. Having a deep understanding of the industry and your customers’ needs enables you to offer tailored solutions that suit their requirements.If only a few years of experience in the lithium industry, it may have a lot to learn.

Generally speaking, li-ion battery manufacturers have a competitive advantage in innovation,because they research and develop new technologies and improve their products for longer time and energy.In addition, experienced battery manufacturers usually have comparatively better customer service. If there is a problem, the company have the ability to help to solve the problem and provide the promised warranty.

Keheng Lithium Battery has been focusing on the lithium battery industry since 2008, with its own battery cell factory and battery assembly factory, long-term cooperation and mutual success is always our pursuit.

2, Complete control of the battery cells supply chain

Different factories have various cost and price system, and the total cost of products are affected by many different factors such as management cost, sales cost, marketing and promotion cost, as well as the supply chain management department, etc. Therefore, it is also important for battery factories to have the ability to get the support of the support supply chain and scale production.It also requires higher quality factory management SOP.

The core component of the lithium batteries is the battery cell, different cells brand, Grade A product or non-A (How to distinguish grade A and grand B battery cells), and the corresponding BMS hardware parts and software all are the factors .

It’s clear that the manufacturer will be your first choice if you can get great value for money. If you are interested in the components of total costs for lithium batteries, we would be happy to share thoughts them with you, please feel free to contact us.

3, Continuous technical support

Even the best products will have product problems, lithium batteries due to their chemical properties, nobody can promise that no damage. We understand how’s important that to choose a supplier with continuous technical support services, can provide technical guidance in the first time when there are problems or questions related to the product which will help you to obtain the satisfaction of your customers.

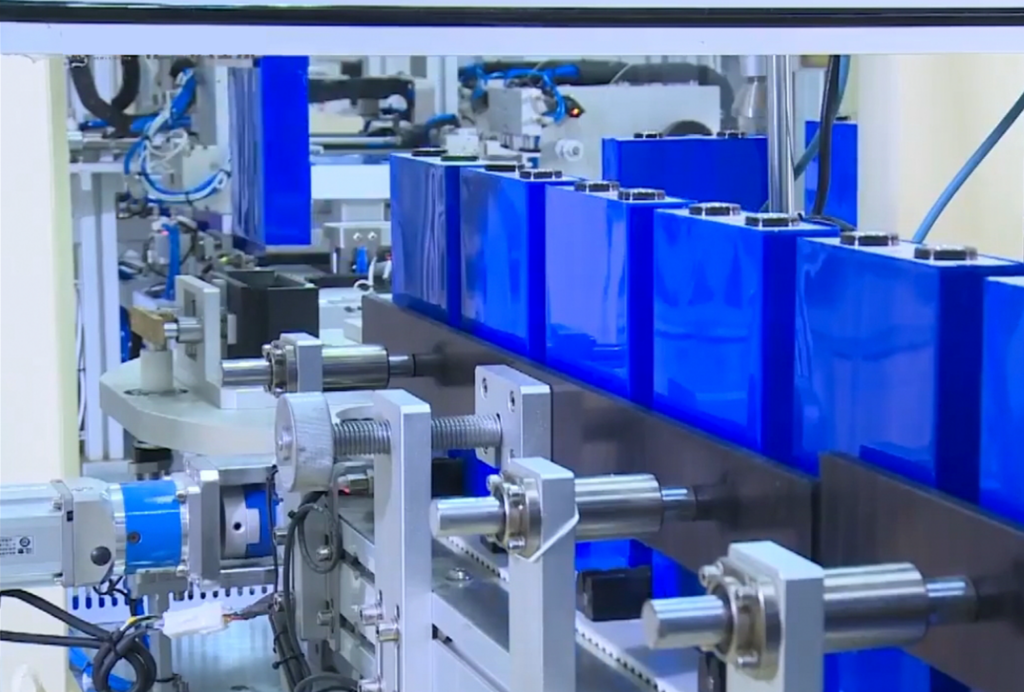

4, Production capacity

The mass production ability determines whether subsequent orders can be delivered in a timely and stable manner.The turnaround time is very important, especially during the peak order season.It can be maddening if the scale of the and once the lead time can’t be determined, subsequent shipments and your cash flow can be affected!

5, Update Technology–R&D

Customer’s demand is upgrading with the change of the local market needs, the new products launching matters. Whether the factory has a research and development department, determines the product is follow the crowd, or with the times!

Continually committed in R&D team, on the one hand, can upgrade the original process, and have the will and ability to improve their own assembly process to enhance market competitiveness;

Secondly, combine with the local market to launch a new series, is also depend on the R&D team. I don’t need to strength to expand the importance of the market.We basically launch new products every month, our R&D will follow the business together to go abroad to better understand the product needs of the international market.

We launched the new wall-mounted all-in-one ess in May 2023, it has helped us to develop 3 distributors within 3 months, and the unique design has also increased revenue for our customers.

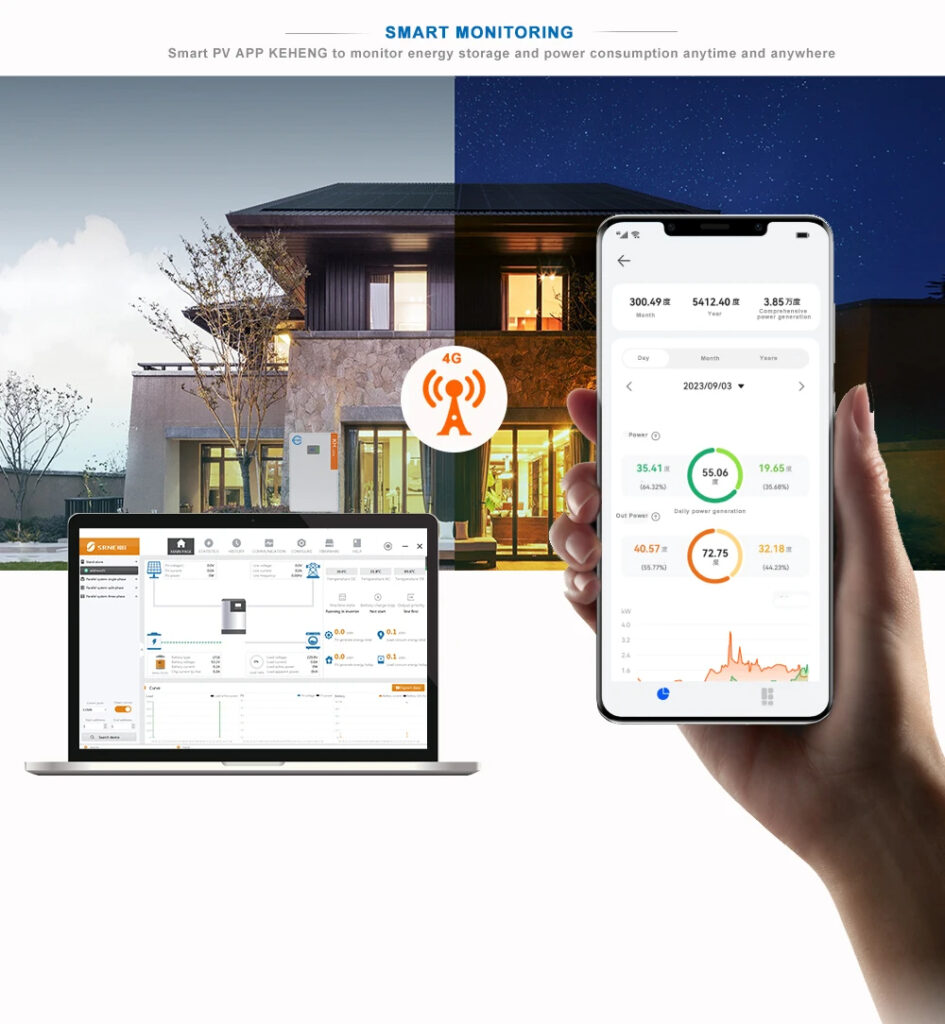

6, Compatibility with inverters & charger

Lithium batteries are often used with inverters, chargers and other ancillary products. In this way, we need to pay more attention to the matching between them. For example, when it comes to battery energy storage systems, we have to talk about the matching between lithium batteries and inverters by CAN/RS485 communication protocols. If the battery matches with mainstream inverter brands on the market, and the BMS debugs in many types of protocols have the influence for customers to expand their local market. For industrial batteries, such as forklift batteries and golf batteries, the matching of the battery and charger protocols can help the charger read the battery parameters so that it can more accurately charge the battery to realize the efficiency of energy use. The same is true for LCD displays.

7, Customization Service

Lithium battery projects always come with customization requirements more or less, such as hardware: size, voltage, capacity, appearance, package, internal structure, etc.; software: BMS software can be independently written, low-temperature function, Bluetooth APP OEM, intelligent BMS can reduce the battery self-discharge, extend the working time and so on.

All the projects in the initial stage need support and coordination from both parties. When you receive a new project with potential opportunities, the supplier has no MOQ, and willingness to provide technical support determines the success of the project.

8, Variety Of Product Line

Lithium batteries with the advantages of being environment-friendly, higher energy density, lighter weight, maintenance-free, and longer service life, etc(lithium battery VS lead acid battery), lithium batteries are gradually replacing the lead-acid battery application market. At present, lithium batteries are widely used as forklift lithium batteries, marine lithium batteries, lithium car batteries, lithium batteries for electric vehicles, solar street lamps, energy storage systems, etc., in every application that has electricity needs. Complete product line will provide you more opportunities. The factory will give you strong support when you want to switch the direction of application, provide mature product lines, and useful market information.

9, Battery Certification

Other one consideration is certification and compliance. Lithium batteries are defined as dangerous goods in the United Nations product catalogue, the rules are very strict for the transportation of lithium batteries, such as UN38.3, MSDS, and sea shipping. Additionally, different national markets have corresponding safety certification requirements for lithium battery products, such as UL, CB(IEC62133), UKCA, CE, PSE, KC, BIS, etc.

10, Mature technology & After-sales service

Lithium-ion battery product warranty and manufacturer’s after-sales service is a prerequisite. Nobody wants to work with a supplier who sells products and then forgets about you. Our Engineers can provide remote online service to ensure after-sales and provide technical support for customer projects.

11, Sales support

Lithium battery manufacturers do not simply sell goods to dealers, need to train them about market information, to provide the necessary sales material, such as: Frequently Asked Questions are compiled into a booklet for customers to use locally to deal with common issues. In addition, if you can provide priority sales support for new product lines, one more selling point! In short, try your best to utilize your dealer network to help your customers gain revenue and snowball. For more details, you can refer to our distributor agency.

12, Full inspection of all components–QC

Product quality is always the core of a product. So strict QC system is important to ensure the quality of the product, QC is generally divided into IQC (incoming quality control) , OQC( Outgoing quality control), and shipping test report, we need to test the incoming and outgoing materials of the battery cell, BMS, battery shell, and other auxiliary materials, and the shipping of the complete battery pack is also required for aging test. We also need to carry out aging test for the complete battery pack.

The above is the main factors to consider when choosing a lithium battery supplier partner, any questions please feel free to contact us.