Introduction

Batteries play a vital role in our modern society, serving as the powerhouse behind a myriad of devices and applications that we rely on daily. From powering our smartphones and laptops to enabling electric vehicles and storing renewable energy, batteries have become indispensable components of our technological landscape. Without batteries, the seamless functioning of many essential tools would be compromised, emphasizing the pivotal nature of these energy storage devices.

Introducing AGM and Lithium-ion Batteries

Among the plethora of battery types available in the market, two prominent contenders are AGM (Absorbent Glass Mat) batteries and Lithium-ion batteries. AGM batteries are a type of lead-acid battery that utilizes Absorbent Glass Mat technology to store and deliver energy efficiently.

On the other hand, Lithium-ion batteries employ lithium chemistry to achieve high energy density and long-lasting performance across various applications. Understanding the nuances between these two types of batteries is crucial for making informed decisions regarding their usage in different scenarios.

The Anatomy of AGM Batteries: Absorbent Glass Mat

Technology and Lead-Acid Composition

AGM batteries, short for Absorbent Glass Mat batteries, are a type of valve-regulated lead-acid (VRLA) battery. These batteries are known for their maintenance-free operation and sealed design, making them ideal for various applications.

The key feature of AGM technology is the presence of a fiberglass mat separator that absorbs and immobilizes the electrolyte solution within the battery. This design allows for efficient oxygen recombination during charging, reducing water loss and extending the battery’s lifespan.

Within an AGM battery, the lead-acid composition consists of lead plates coated with lead dioxide (positive plate) and spongy lead (negative plate). The plates are immersed in an electrolyte solution made of sulfuric acid diluted with distilled water.

The Absorbent Glass Mat serves as a sponge-like medium that holds the electrolyte between the plates while preventing spillage or leakage. This structure enhances both the electrical conductivity within the battery and its resistance to vibration or impact, making AGM batteries suitable for rugged applications such as off-grid power systems or marine use.

The Marvels of Lithium Chemistry: Anode, Cathode, and Electrolyte Components

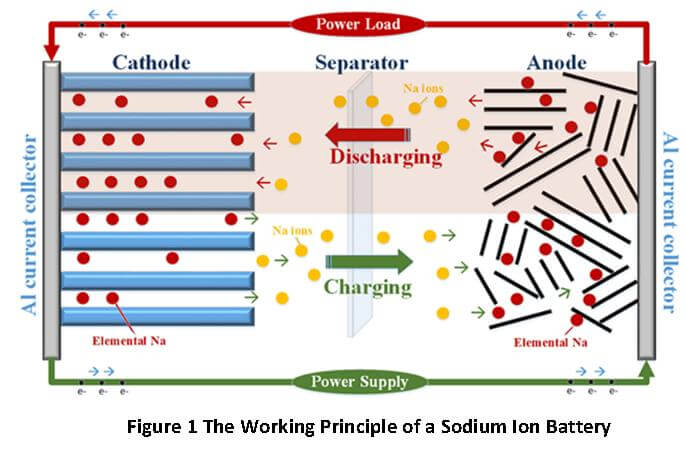

Lithium-ion batteries revolutionized energy storage with their high energy density and lightweight construction. At the heart of these batteries lies lithium chemistry, where lithium ions shuttle between the anode and cathode during charge-discharge cycles. The anode in a lithium-ion battery typically consists of graphite material that intercalates lithium ions during charging processes.

This reversible process allows for efficient energy storage without compromising stability. The cathode in a lithium-ion battery plays a crucial role in determining its performance characteristics.

Common cathode materials include lithium cobalt oxide (LCO), lithium iron phosphate (LFP), or nickel manganese cobalt oxide (NMC). Each cathode material offers unique benefits in terms of energy density, cycle life, and safety features.

The electrolyte component in lithium-ion batteries is usually a non-aqueous solution containing lithium salt dissolved in organic solvents. This electrolyte facilitates ion conductivity between the anode and cathode while ensuring thermal stability under varying operating conditions.

Energy Density Comparison AGM and Lithium-ion Batteries

When comparing AGM and Lithium-ion batteries in terms of energy density, it becomes evident that Lithium-ion batteries have a significantly higher capacity for energy storage compared to AGM batteries. The energy density of a battery refers to the amount of energy it can store per unit volume or weight. Lithium-ion batteries have a higher energy density, allowing them to store more energy in a smaller and lighter package than AGM batteries.

This makes Lithium-ion batteries ideal for applications where space and weight are crucial factors. Furthermore, the capacity for energy storage in Lithium-ion batteries is impressive due to their composition of lightweight lithium compounds.

This allows them to hold more charge per unit weight compared to AGM batteries, making them preferred in high-demand applications where longer periods between recharging are essential. The higher capacity of Lithium-ion batteries also translates into longer run times for devices powered by them, providing extended usage without the need for frequent recharges.

Weight-to-Energy Ratio AGM and Lithium-ion Batteries

In the realm of battery technology, the weight-to-energy ratio plays a crucial role in determining the efficiency and practicality of a power source. When comparing AGM and Lithium-ion batteries, it becomes apparent that Lithium-ion batteries offer a superior weight-to-energy ratio. Their lightweight composition and higher energy density allow them to deliver more power while keeping overall battery weight minimal.

This is particularly advantageous in portable electronic devices or electric vehicles where reducing weight can lead to enhanced performance and increased efficiency. On the other hand, AGM batteries have a lower weight-to-energy ratio compared to Lithium-ion counterparts.

The lead-acid construction of AGM batteries contributes to their heavier weight relative to the amount of stored energy they provide. While AGM batteries are known for their robustness and reliability in certain applications, their lower weight-to-energy ratio may limit their suitability for use cases that prioritize portability and reduced bulkiness.

Charging Efficiency Comparison AGM and Lithium-ion Batteries

When evaluating charging efficiency between AGM and Lithium-ion batteries, several factors come into play that influence how effectively each type can retain and utilize stored charge. Charge retention capabilities refer to how well a battery holds onto its stored power over time without significant loss or leakage. In this aspect, both types exhibit differences based on their chemistry and design.

Lithium-ion batteries typically excel in charge retention capabilities due to their low self-discharge rate compared to AGM counterparts. This means that even when idle or not actively used, Lithium-ion batteries retain more of their stored charge over extended periods without experiencing significant power loss.

On the other hand, AGM batteries may exhibit slightly higher self-discharge rates which could impact overall charging efficiency when left unused for prolonged durations. Charging speed is another crucial aspect influencing charging efficiency between these two types of batteries.

Technological Differences

Internal Resistance

Internal resistance is a crucial aspect that sets AGM and Lithium-ion batteries apart in terms of performance. AGM batteries typically have higher internal resistance compared to Lithium-ion batteries. This difference has a significant impact on the overall efficiency and effectiveness of the battery system.

Higher internal resistance in AGM batteries leads to energy losses during charging and discharging processes, affecting the battery’s ability to deliver power consistently. Moreover, the higher internal resistance in AGM batteries results in reduced efficiency, as more energy is dissipated as heat rather than being utilized for powering devices or vehicles.

On the contrary, Lithium-ion batteries exhibit lower internal resistance, allowing for faster charging and discharging rates with minimal energy loss. This feature contributes to improved performance and better overall efficiency in various applications where quick power delivery is essential.

Cycle Life

Another critical technological difference between AGM and Lithium-ion batteries lies in their cycle life characteristics. Cycle life refers to the number of charge-discharge cycles a battery can undergo before experiencing significant capacity degradation.

In general, Lithium-ion batteries have a longer cycle life compared to AGM batteries due to their inherent chemistry and design. Factors such as depth of discharge, temperature fluctuations, charging protocols, and usage patterns play a crucial role in determining the cycle life of both types of batteries.

While AGM batteries are known for their reliable performance over multiple cycles, they tend to exhibit shorter cycle life spans compared to their Lithium-ion counterparts. This difference makes Lithium-ion batteries more suitable for applications that require prolonged battery longevity and consistent performance over an extended period.

The technological variances between AGM and Lithium-ion batteries highlight the intricate design differences that influence their performance capabilities and longevity attributes.

Understanding factors like internal resistance and cycle life can aid consumers and industries in selecting the most suitable battery technology for their specific requirements. By delving deeper into these technological disparities, one can appreciate the nuanced complexities that define how AGM and Lithium-ion batteries function within various applications while considering their impact on overall efficiency, performance, and endurance.

Application Specifics

AGM Batteries

Amid the technological advancements in automotive industry, AGM batteries have found a niche in powering start-stop systems. These systems are designed to automatically shut off the engine when the vehicle comes to a stop, such as at a traffic light, and smoothly restart it when acceleration is needed.

The high cycling capability and low self-discharge rate of AGM batteries make them ideal for this application, ensuring reliable performance even with frequent engine restarts. The ability of AGM batteries to provide instant power also contributes to improved fuel efficiency in vehicles equipped with start-stop technology.

Moving from roads to waters, AGM batteries show their versatility in marine applications, particularly in boat engines. The durable construction of AGM batteries allows them to withstand the harsh marine environment, including vibrations and rough seas.

Boaters rely on AGM batteries to power essential electronics onboard such as navigation systems, lights, pumps, and communication devices. Their maintenance-free operation and leak-proof design make them a popular choice among boat owners seeking reliable power sources for extended periods out at sea.

Lithium-ion Batteries

In consumer electronics, lithium-ion batteries have revolutionized the way we stay connected in the digital world. Smartphones, laptops, tablets – these ubiquitous gadgets rely on the energy density and lightweight nature of lithium-ion batteries to provide long-lasting power in a compact design.

The high voltage output of lithium-ion batteries allows devices to operate efficiently while maintaining a sleek profile that meets modern aesthetic preferences.

Lithium ion plays an unparalleled role in marine ESS, ensuring that all programs run smoothly. Li-ion is not only advantageous in the ocean but also in C&l energy storage system, Home Battery Backup

The shift to electric vehicles (EVs) as a sustainable transportation solution is one of the most promising applications for lithium-ion technology. EV manufacturers are capitalizing on the superior energy density and longevity of lithium-ion batteries to propel vehicles to zero emissions on the road.

The scalability of lithium-ion battery packs allows for customized configurations based on vehicle size and range requirements for material transportation. Ensure dominance in the field of lithium forklift batteries and AGV batteries.

Recycling Options: AGM And Lithium-ion Batteries

When it comes to recycling batteries, both AGM and Lithium-ion batteries present unique challenges and opportunities. AGM batteries, being lead-acid based, have a long history of recycling infrastructure in place. The lead components can be melted down and reused in new batteries or other products.

However, the acid must be carefully neutralized and disposed of properly to prevent environmental harm. In contrast, recycling lithium-ion batteries involves more complex processes due to their composition of various metals like lithium, cobalt, and nickel.

These elements are valuable but require specialized recycling facilities equipped to handle the extraction process effectively. The challenge lies in recovering these materials efficiently while minimizing energy consumption and environmental impact.

Overall, both types of batteries can be recycled effectively with the right technologies and processes in place. Continued research into improving recycling methods for lithium-ion batteries is crucial to maximize resource recovery and minimize waste.

Environmental Considerations: Disposal or Recycling Processes

The disposal or recycling processes for AGM and Lithium-ion batteries have significant implications for the environment. Improper disposal can lead to leaching of toxic substances into soil and water sources, posing risks to ecosystems and human health. This highlights the importance of implementing strict regulations on battery disposal practices.

Lithium-ion batteries, in particular, contain hazardous materials that need careful handling during dismantling and recycling. Without proper safeguards in place, there is a risk of fires or explosions due to thermal runaway caused by improper storage or handling procedures.

By contrast, AGM batteries are relatively safer during disposal but still require responsible management to prevent environmental contamination from lead exposure. Both types of batteries demand transparent tracking systems from production through use to end-of-life stages to ensure proper handling at all points along the supply chain.

Sustainability Factors: Battery Production

The sustainability factors related to battery production encompass a wide range of considerations beyond just raw material extraction. Energy-intensive processes involved in manufacturing both AGM and Lithium-ion batteries contribute significantly to their overall environmental footprint. Lithium-ion battery production is known for its high energy requirements due to complex manufacturing steps like electrode coating and cell assembly performed under controlled environments with specific temperature conditions.

On the other hand, AGM battery production also requires substantial energy inputs but may have a lower carbon footprint compared to lithium-ion if sourced from recycled lead materials. To enhance sustainability in battery production across both types, efforts are underway towards increasing efficiency in manufacturing processes, reducing waste generation through improved technology utilization like automation systems for higher precision operations leading to minimized resource consumption per unit produced.

Cost Considerations

Initial Purchase Costs: Balancing Investment and Value

When it comes to initial purchase costs, AGM batteries tend to be more affordable than their Lithium-ion counterparts. This is largely due to the simpler technology and mature manufacturing processes of AGM batteries, making them a cost-effective choice for many applications.

On the other hand, Lithium-ion batteries are known for their higher upfront costs due to the complex production process and expensive raw materials involved in their manufacturing. While the initial investment might be higher with Lithium-ion batteries, their longer lifespan and superior performance can often justify the cost in the long run.

Long-term Cost Analysis: Factoring in Maintenance Expenses

In terms of long-term cost analysis, it is essential to consider maintenance expenses when comparing AGM and Lithium-ion batteries. AGM batteries typically require minimal maintenance compared to Lithium-ion batteries, which may need specialized care such as balancing charging cycles and temperature control to optimize performance and longevity.

While AGM batteries may have lower upfront costs and simpler maintenance requirements, they have a limited cycle life compared to Lithium-ion batteries, which can withstand more charge-discharge cycles over time. Therefore, the long-term cost analysis must take into account not only the initial purchase price but also ongoing maintenance needs for both types of batteries.

Conclusion

When weighing the cost considerations between AGM and Lithium-ion batteries, it is crucial to look beyond just the initial purchase price. While AGM batteries offer affordability upfront and minimal maintenance requirements, Lithium-ion batteries provide superior performance and longevity that can translate into long-term savings despite their higher initial investment. Understanding your specific needs and usage patterns will help determine which type of battery would be more cost-effective in the context of your application.

Ultimately, investing in high-quality energy storage solutions like Lithium-ion batteries can lead to greater efficiency, reliability, and overall value in the long run. Embracing advancements in battery technology not only benefits us economically but also contributes positively towards a sustainable future powered by innovative energy solutions.

Frequently Asked Questions about AGM Batteries and Lithium-Ion Batteries

AGM batteries typically have a lower initial cost compared to lithium-ion batteries.

Lithium-ion batteries have a longer lifespan and require less maintenance, resulting in lower long-term costs.

AGM batteries are better suited for high demand applications due to their high capacity and high power output capability.

Lithium-ion batteries are considered more environmentally friendly due to their lower toxicity, longer lifespan, and reduced overall impact on the environment.

AGM batteries are commonly used in automotive starting, lighting and ignition (SLI) batteries, as well as renewable energy systems and backup power.

Lithium-ion batteries are widely used in portable electronics, electric vehicles, and home and commercial energy storage systems.

When choosing between AGM batteries and lithium-ion batteries, consider your usage patterns, environmental impact, and budget. For high power consumption devices, Li-ion batteries may be the best choice due to their high energy density. On the other hand, for low-drain devices, alkaline batteries may be sufficient and more cost-effective.

1 thought on “A Comprehensive Comparison of AGM and Lithium-ion Batteries”

>to cover 1 TWh (0.025 of the US demand), 625 of these 1.6 GWh facilities would be requiredOr, if you’re clever, just build 2 and use them every day instead of once per year, since we’re talking about yearly electricity demand.