Introduction

The Definition of Charging Voltage

Charging voltage refers to the electrical potential applied to a battery to facilitate the flow of current into it, replenishing its energy reserves. In the case of a lithium battery, this voltage is crucial as it determines how efficiently and safely the battery can be recharged. Understanding the correct charging voltage for lithium batteries is paramount in ensuring their longevity and performance.

The Influence of Battery Chemistry on Charging Voltage

The type of battery chemistry, such as lithium-ion or lithium-polymer, plays a significant role in determining the appropriate charging voltage. Different chemistries have specific voltage requirements for optimal charging efficiency and safety. For instance, lithium-ion batteries typically have a higher nominal voltage compared to lithium-polymer batteries, necessitating different charging protocols.

Considering Capacity, Size, and Temperature in Charging Voltage Selection

Apart from battery chemistry, factors like the capacity and size of the battery also influence the ideal charging voltage. Larger-capacity batteries may require higher voltages to charge effectively, while smaller ones need more precise control to avoid overcharging.

Additionally, temperature variations can impact how a lithium battery accepts charge, with extreme temperatures either speeding up or slowing the charging process. It is essential to factor in these variables when determining the optimal charging voltage for lithium batteries.

Optimal 3.7V Lithium Battery Charging Voltage

Explanation of the Nominal 3.7V Lithium Batteries Charging Voltage

When we refer to the nominal voltage of a lithium battery, we are essentially discussing its average or standard operating voltage. For a 3.7V lithium battery, this represents the typical voltage level at which the battery operates during its discharge cycle. It is important to note that while the nominal voltage is labeled as 3.7V, the actual voltage range can vary slightly depending on factors such as temperature, load, and state of charge.

This variation is due to the chemical composition and design of lithium batteries, which allow for flexibility in their performance. The 3.7V nominal voltage is common among lithium-ion and lithium-polymer batteries, making it a popular choice for various portable electronic devices such as smartphones, laptops, and power banks.

This specific voltage level strikes a balance between energy density and stability, ensuring efficient power delivery while maintaining safety standards. Understanding this nominal voltage is crucial when selecting an appropriate charging method to avoid overcharging or undercharging that could potentially damage the battery and compromise its longevity.

3.7V lithium battery float and cut-off voltage explanation

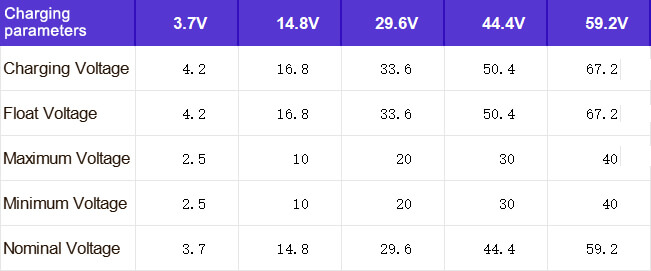

The lithium battery industry has not only nominal voltage, but also float voltage and cut-off voltage, for 3.7V lithium battery, the float voltage is 4.2V and cut-off voltage is 2.5V, the actual situation will be slightly different according to the temperature, load and state of charge and other factors.

Importance of Selecting the Correct Charging Voltage to Ensure Battery Longevity and Safety

Choosing the correct charging voltage for a 3.7V lithium battery is paramount in maximizing its lifespan and preserving its safety features. When a lithium battery is charged with an incorrect voltage level, several detrimental effects can occur. Overcharging can lead to thermal runaway or even cause the battery to swell or leak dangerous chemicals.

On the other hand, undercharging may result in decreased capacity and overall performance degradation over time. To ensure optimal longevity and safety of a 3.7V lithium battery, it is essential to adhere to manufacturer specifications regarding charging voltages and current levels recommended for that particular battery model.

By following these guidelines diligently, users can prevent premature aging of their batteries, minimize potential risks of fire or explosion due to improper charging practices, and ultimately extend the overall lifespan of their devices powering these batteries.

Charging Methods for 3.7V Lithium Batteries

Constant Voltage Charging

In the realm of lithium battery charging, constant voltage charging stands as a prominent method employed to replenish and maintain the energy levels of 3.7V lithium batteries. This technique involves applying a steady voltage level across the battery terminals during the final stage of charging to ensure a controlled and gradual influx of energy. By maintaining a fixed voltage, typically equivalent to the nominal voltage of the battery (in this case, 3.7V), constant voltage charging minimizes the risk of overcharging and safeguards the battery against potential damage or performance degradation.

Moreover, a crucial aspect that characterizes constant voltage charging is its distinctive charging curve. The charging curve represents how the battery voltage changes over time during the charging process.

Initially, when current is supplied to the battery, its voltage increases gradually until it reaches its peak level at which point it stabilizes due to the application of constant voltage. Observing and analyzing this curve is essential for determining when to terminate the charging process efficiently and prevent any adverse effects on the battery’s health and longevity.

Constant Current/Constant Voltage (CC/CV) Charging

A more sophisticated approach in lithium battery charging methodology is Constant Current/Constant Voltage (CC/CV) Charging, where both current and voltage are regulated throughout different stages of the process to optimize efficiency and safety. In this method, initially, a controlled amount of current is provided to swiftly charge up the lithium battery until it reaches a predefined threshold known as ‘constant current’ phase.

Subsequently, upon reaching this stage, it transitions into ‘constant voltage’ mode where a fixed voltage—often matching with 3.7V for these batteries—is maintained while allowing reducing current flow as per requirements. The advantages embedded within CC/CV Charging are manifold; foremost being its capability for fast-charging scenarios without compromising on safety or long-term durability concerns associated with lithium batteries.

By intelligently managing both current and voltage levels during different phases of charging cycle effectively ensures swift yet controlled replenishment of energy reserves within 3.7V lithium batteries while averting risks like overheating or overcharging that could jeopardize their overall functionality or lifespan. Through strategic incorporation in various devices ranging from smartphones to electric vehicles where rapid recharging is imperative yet maintaining optimal performance standards remains paramount—CC/CV Charging methodology rightfully carves out its niche as a versatile solution catering to diverse fast-charging needs across multiple technological domains.

Charging Safety Considerations for Lithium Batteries

Importance of Using a Dedicated Charger Designed for Lithium Batteries

When it comes to charging lithium batteries, using a dedicated charger specifically designed for these batteries is paramount. Lithium batteries require precise charging parameters to ensure their longevity and safety.

Generic chargers may not provide the necessary safeguards and could potentially overcharge or overheat the battery, leading to catastrophic consequences such as leakage, fire, or even explosions. A dedicated lithium battery charger typically incorporates features like voltage regulation, current limiting, and temperature monitoring to prevent any mishaps during the charging process.

Tips to Prevent Overcharging, Overheating, and Other Safety Risks

To extend the lifespan of your 3.7V lithium battery and ensure safe charging practices, there are several crucial tips to keep in mind. Firstly, always charge your lithium battery in a well-ventilated area away from flammable materials or sources of heat.

Avoid leaving the battery on charge unattended for extended periods to minimize the risk of overcharging. Additionally, it is vital to use high-quality cables and connectors that can handle the charging currents without overheating or causing voltage drops that may lead to overcharging.

Remember also never to expose lithium batteries to extreme temperatures while charging or discharging as this can compromise their performance and safety. It is advisable not to store fully charged lithium batteries for prolonged periods as this can accelerate their degradation process.

Regularly inspect your battery charger for any signs of damage or malfunction that could pose risks during the charging process. By following these precautions diligently, you can ensure the safe and efficient operation of your 3.7V lithium battery while maximizing its lifespan.

Advanced Techniques in Lithium Battery Charging

Pulse Charging Technology: Energizing Efficiency

The concept of pulse charging technology involves delivering energy to a lithium battery in intermittent pulses rather than a continuous flow. This technique allows for more precise control over the charging process, minimizing heat generation and reducing the risk of overcharging.

By pulsing the charging current, it helps prevent dendrite formation, which can cause short circuits and degrade battery performance over time. Pulse charging is particularly effective for rejuvenating older lithium batteries that may have experienced some capacity loss.

Moreover, pulse charging technology can enhance the overall efficiency of the charging process by optimizing energy transfer to the battery cells. The rapid on-off cycling of current pulses helps to reduce internal resistance within the battery, leading to faster and more effective charging.

This method also promotes better energy utilization and can extend the lifespan of lithium batteries by preventing issues like electrolyte decomposition or metal plating on electrodes. Implementing pulse charging technology requires sophisticated control circuitry but offers substantial benefits in terms of battery performance and longevity.

Temperature-Controlled Charging Methods: Maintaining Optimal Conditions

Temperature plays a crucial role in lithium battery performance and longevity, making temperature-controlled charging methods essential for maximizing efficiency and safety during the charging process. These methods involve monitoring and adjusting the charging parameters based on real-time temperature readings to ensure that the battery remains within its optimal operating range.

By maintaining a stable temperature environment, excessive heat buildup that can accelerate degradation or even lead to thermal runaway is prevented. Implementing temperature-controlled charging methods helps mitigate potential risks associated with extreme temperatures during both charging and discharging cycles.

When a lithium battery operates outside its recommended temperature range, it can impact not only its immediate performance but also long-term reliability. Temperature sensing technologies integrated into chargers enable precise regulation of voltage and current flow according to ambient conditions, promoting safe and efficient recharging practices while safeguarding both the battery’s health and user well-being.

Impact of High-Frequency Pulsing on Battery Performance: Harmonizing Efficiency

High-frequency pulsing refers to rapidly switching between charge/discharge states at frequencies beyond standard pulse rates. This technique provides finer control over energy input/output levels, offering increased precision in managing state-of-charge levels within lithium batteries. High-frequency pulsing can help equalize cell voltages across a multi-cell pack more effectively than conventional methods while limiting stress-induced imbalances that could compromise overall system integrity.

Furthermore, high-frequency pulsing has been shown to promote electrochemical reactions within lithium batteries that contribute to improved overall performance characteristics such as cycle life and charge acceptance rates. By applying this advanced technique strategically during portions of the charge/discharge cycle where higher power demands are prevalent, manufacturers can optimize efficiency without sacrificing long-term durability or stability.

Case Studies and Real-World Applications

Examples of devices using 3.7V lithium batteries

In the realm of portable electronics, 3.7V lithium batteries are ubiquitous due to their high energy density and reliable performance. Smartphones, tablets, and wearables such as smartwatches all utilize 3.7V lithium batteries to power their operations efficiently. These devices require a steady and reliable power source to support their functionalities throughout the day, making lithium batteries an ideal choice for such applications.

The lightweight and compact nature of these batteries also align well with the sleek designs of modern gadgets. Moreover, drones have revolutionized various industries like photography, agriculture, and surveillance with their aerial capabilities.

Many drones rely on 3.7V lithium batteries for their power needs due to the battery’s ability to provide high energy output in a lightweight package. The use of lithium batteries in drones has enabled longer flight times and improved overall performance, showcasing the crucial role these batteries play in advancing technology.

Success stories in optimizing battery life through proper charging techniques

One notable success story in optimizing battery life through proper charging techniques comes from the electric vehicle (EV) industry. EV manufacturers have implemented sophisticated charging systems that carefully regulate the charging voltage of 3.7V lithium batteries to extend their lifespan and improve overall efficiency.

By utilizing smart charging algorithms that adjust voltage levels based on battery conditions, EVs can maximize range while maintaining battery health over the long term. Furthermore, medical devices that rely on 3.7V lithium batteries have seen significant improvements in battery longevity by employing tailored charging strategies.

Devices like insulin pumps and portable defibrillators require consistent power supply for critical functions, making efficient battery management essential. Through customized charging protocols that account for factors like temperature variations and discharge patterns, these medical devices can operate reliably without compromising patient safety or device performance.

Conclusion

The field of lithium battery technology is continually evolving, driven by innovation and a commitment to sustainability. With advancements in solid-state batteries, AI integration, and eco-friendly materials, the future looks promising for energy storage solutions.

By staying at the forefront of these trends and embracing new technologies responsibly, we can create a more efficient, environmentally friendly world powered by cutting-edge lithium battery technology. Let’s look forward to a future where our devices are powered by safe, high-performance 3.7V Lithium Battery Charging Voltage, making a positive contribution to our lives and the planet!