Introduction.

Lithium-ion batteries have become ubiquitous in our modern society, from smartphones to electric cars. As consumers, we rely heavily on these energy storage devices to keep our devices running smoothly and efficiently.

However, many of us tend to overlook the importance of monitoring the health of our lithium-ion batteries. Just like any other component, batteries degrade over time, which can lead to decreased performance and potential safety hazards if not properly maintained.

The Importance of Monitoring the Health of Lithium-Ion Batteries

Regularly monitoring the health of lithium-ion batteries is critical for several reasons. Firstly, by monitoring the condition of your battery, you can ensure that your device continues to operate at its best.

Aging batteries can lead to shorter battery life, increased charging times, and ultimately affect the overall user experience. Additionally, failing lithium-ion batteries pose safety risks, such as swelling and even catching fire in extreme cases.

Additionally, proactively monitoring the health of your battery allows you to identify potential issues early and take the necessary steps before they escalate. By remaining vigilant and aware of your battery’s condition, you can extend the life of your battery and avoid unplanned downtime or costly repairs.

Signs and Symptoms of Lithium Ion Battery Failure

Recognizing the signs of a failing lithium-ion battery is vital for every gadget owner. A common symptom is rapid discharge – if you notice that your device is draining much faster than usual despite minimal use, this could be a sign that the battery is deteriorating. Declining capacity can also manifest itself in the form of the device suddenly shutting down during use or erratic percentage jumps.

Another sign to watch out for is overheating during charging or discharging. Lithium-ion batteries shouldn’t overheat during normal operation; therefore, if you notice your device emitting unusual amounts of heat when connected to a power source or during frequent use, this could indicate a potential problem with the battery’s internal components.

Voltage for Battery Health

Voltage readings are an important aspect of determining the health of a lithium-ion battery. By monitoring voltage levels, you can gain insight into the overall condition and performance of the battery.

Fully charged lithium ternary batteries typically have a voltage of between 4.2 and 4.3 volts per cell, depending on the particular chemistry and design. As the battery is discharged, the voltage will gradually decrease to approximately 3.0 volts per cell near depletion.

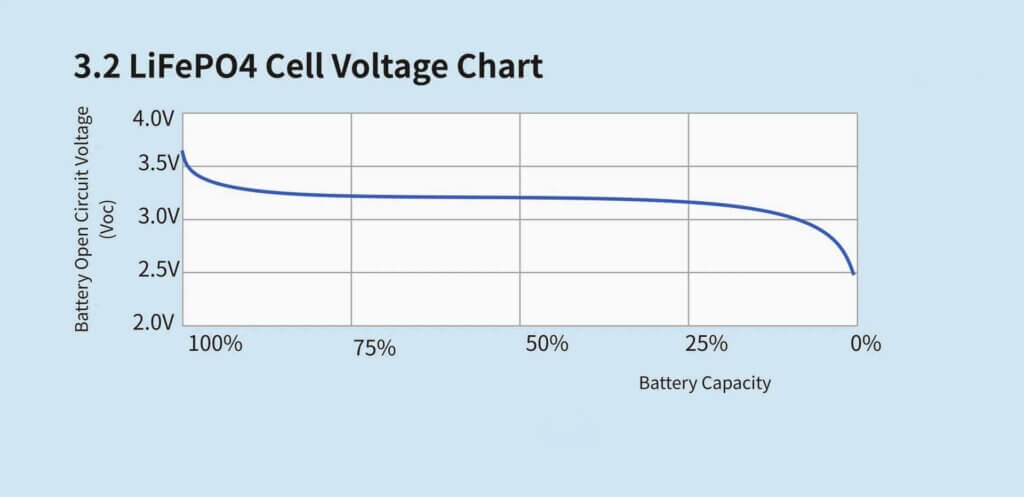

In the case of Lithium Iron Phosphate batteries, the voltage of a fully charged battery is 3.6 V. The voltage of the battery will gradually increase depending on the number of series connections.

Abnormal voltage readings may indicate a potential battery problem such as overcharging, over-discharging, or internal wear. A sudden drop in voltage during use or charging may indicate a loss of battery power or an increase in internal battery resistance.

Regularly measuring and recording voltage readings at different stages of charging can help track trends and identify abnormalities that may require further investigation or maintenance. Properly understanding voltage readings can also help optimise charging habits and extend battery life.

By understanding how voltage levels correspond to state of charge and capacity, users can implement effective charging strategies and avoid unnecessary stress on the battery. Continuous monitoring of voltage readings provides an early warning of potential malfunction or deterioration, so proactive measures can be taken to prevent further damage or safety hazards.

The “Lithium battery voltage” page is a good introduction to the Lifepo4 battery voltage chart, click for more!

Capacity Testing

Capacity testing is a comprehensive evaluation tool to accurately assess the energy storage capacity of lithium-ion batteries. Capacity measurement involves determining how much energy a battery is capable of storing and delivering under specific conditions, thus reflecting the health and performance potential of the battery.

The rated capacity of a lithium-ion battery is usually expressed in Ampere-hours (Ah) or milliampere-hours (mAh), indicating its total energy storage capacity. Periodic capacity testing of lithium-ion batteries helps to establish a baseline performance indicator and track degradation over time due to factors such as usage patterns, environmental conditions and aging processes.

By comparing the actual tested capacity to the initial rated capacity, users can measure the degree of retention or loss of energy storage capacity since initial use. Significant decreases in measured capacity may indicate wear mechanisms such as electrode degradation or electrolyte breakdown within the battery.

Advanced diagnostic techniques, such as coulometric counting or impedance spectroscopy, can be used to perform accurate capacity tests in a controlled laboratory environment, providing a detailed understanding of a battery’s internal behaviour. These methods allow researchers and engineers to accurately analyse charge/discharge curves, internal resistance changes, and electrochemical processes that affect overall energy storage efficiency.

Causes of lithium-ion battery failure

Overcharging

Overcharging is a common cause of lithium-ion battery failure, which occurs when a battery receives more charging current than it can safely handle. Overcharging causes degradation of the electrolyte and electrode materials of the battery, which affects the overall capacity and life of the battery.

Overcharging can lead to the formation of lithium metal within the battery, causing irreversible chemical changes that can trigger thermal runaway – a dangerous chain reaction that causes the battery to overheat and possibly catch fire or explode. Overcharging lithium-ion batteries must be avoided to ensure their longevity and safety.

Over-discharge

Overdischarge occurs when a battery’s discharge voltage falls below the specified minimum voltage level, causing irreversible damage to its internal components. This phenomenon reduces the capacity of the battery and can lead to performance problems such as voltage degradation and reduced energy density.

Over-discharged batteries are also at risk of internal short-circuiting, which can further accelerate battery ageing and increase the likelihood of catastrophic failure. Monitoring discharge levels and avoiding deep discharges are key measures to protect the health of lithium-ion batteries.

Physical Damage

Physical damage poses a significant threat to lithium-ion batteries by destroying their structural integrity and electrical insulation. External forces such as impact, puncture or crush can deform the cell, rupture the inner layers or create unintended electrical pathways within the pack, all of which increase the risk of a thermal runaway event.

Even minor physical damage can weaken the protective function of the battery and escalate into a major safety hazard if not addressed in a timely manner. Proper handling, storage and transport practices are critical to preventing lithium-ion batteries from failing due to physical damage.

Manufacturing Defects

Manufacturing defects include a variety of problems that occur during the production of lithium-ion batteries – from inconsistent thickness of electrode coatings to impurities in the electrolyte solution. These defects can manifest themselves as uneven cell capacity, poor electrode adhesion or insufficient diaphragm material, all of which contribute to premature battery failure. Early detection and correction of manufacturing defects through quality control measures is essential to ensure product reliability and user safety of lithium-ion batteries.

Signs of a poor lithium-ion battery

Rapid discharge

One of the common signs of lithium-ion battery failure is rapid discharge. During normal use, lithium-ion batteries discharge gradually as they power devices.

However, when the battery is nearing the end of its lifespan or experiencing degradation, it may discharge much faster than usual. This rapid discharge can be attributed to the voltage drop that occurs as the battery struggles to maintain a charge.

When a lithium-ion battery experiences a voltage drop during discharge, it is an indication that the internal components of the battery are degrading. As the battery ages, its ability to hold and deliver power decreases, leading to fluctuations in voltage levels during operation.

This voltage drop not only affects the runtime of the device, but also its overall performance and responsiveness. The impact of rapid discharge on device performance can be significant.

Devices powered by failed lithium-ion batteries may exhibit symptoms such as sudden shutdowns even when the display is fully charged, reduced screen brightness or audio volume, and slower processing speeds. Recognising these performance issues as potential signs of battery failure can help prevent unexpected failures and downtime.

Overheating

Another important sign of lithium-ion battery failure is overheating during charging or discharging. Lithium-ion batteries can overheat for a variety of reasons, such as overcharging, high ambient temperatures, internal short circuits, or physical damage to the cell. When a lithium-ion battery reaches an unsafe temperature during operation, it can pose a serious safety hazard to equipment users and the surrounding environment.

The causes of overheating in lithium-ion batteries are multiple, but are usually related to problems with the internal cell structure. As a result of inefficient energy transfer or accelerated chemical reactions, heat builds up inside the battery and, if not mitigated in time, thermal runaway – a potentially dangerous chain reaction – can occur.

Elevated temperatures not only accelerate battery degradation, but also increase the risk of thermal events such as fires or explosions. The safety issues associated with overheating lithium-ion batteries cannot be overemphasised.

In addition to the physical risks and potential fire hazards associated with high temperatures, prolonged exposure to heat accelerates chemical decomposition within the battery cell, leading to irreversible damage and reduced capacity over time. Monitoring temperature levels during the charging cycle and promptly addressing any abnormal heat generation is a critical step in maintaining the safe operation of lithium-ion battery powered equipment.

The Memory Effect of Lithium-Ion Batteries

The phenomenon of the memory effect in lithium-ion batteries occurs when the battery “remembers” its most frequent state of charge and gradually loses capacity over time. This can lead to reduced performance and shorter battery life. For example, if a battery is consistently recharged after only being discharged halfway, it may begin to provide only half of its original capacity.

The impact of the memory effect on battery performance can be significant, causing devices to run out of power more quickly and require more frequent recharging. The key to mitigating the memory effect of lithium-ion batteries is to develop proper charging habits.

Avoid leaving the battery in a high or low charge state for long periods. Instead, fully discharge and recharge the battery regularly to maintain its full capacity.

In addition, occasional deep discharges can help reset battery memory and restore the battery to its full potential. By paying attention to how lithium-ion batteries are used and charged, the effects of the memory effect can be minimised and the life of the battery extended.

Testing Faulty Lithium-Ion Batteries

Tools needed to test lithium-ion batteries

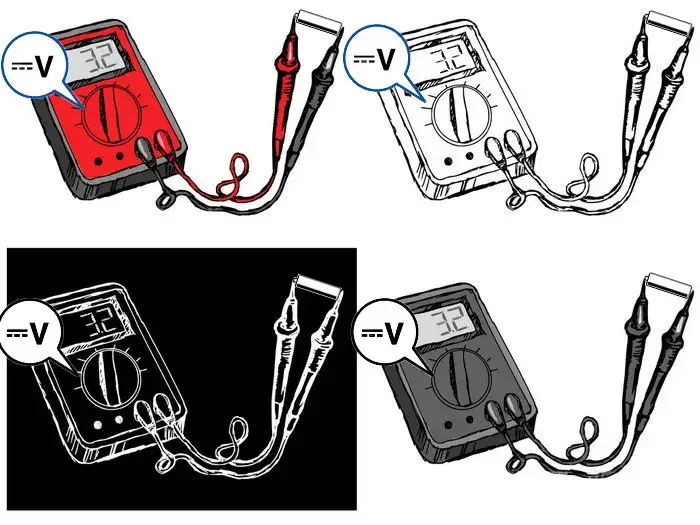

To accurately assess the condition of a lithium-ion battery, several tools must be used for effective testing. A multimeter is necessary to measure the voltage levels at different points of the battery pack. This tool can help identify any voltage inconsistencies that may indicate an internal malfunction within the battery.

In addition, a thermal imaging camera is also important for detecting hot spots or unusual temperature distributions within the battery pack, which could indicate potential problems such as internal short circuits or overcharging. In addition to traditional test tools, specialist equipment such as impedance analysers provide a detailed understanding of the internal resistance and impedance characteristics of lithium-ion batteries.

These analysers have advanced diagnostic capabilities that help pinpoint specific faults or degradation mechanisms that affect battery performance over time. In addition, a dedicated battery management system (BMS) monitors key parameters such as state of charge, state of health and temperature in real time to ensure safe operation and optimal performance of lithium-ion battery systems.

Voltage Testing with a Multimeter

One of the primary methods used when testing a faulty lithium-ion battery is to perform a voltage test using a multimeter. To begin the test, make sure the battery is disconnected from any equipment and is switched off. Set the multimeter to the appropriate voltage setting and connect the positive lead to the positive terminal of the battery and the negative lead to the negative terminal of the battery.

Record the voltage reading displayed on the multimeter. Interpreting the voltage readings is critical to determining the problem with the lithium-ion battery.

Fully charged lithium-ion batteries typically read around 4.2 volts per cell. A significantly low voltage reading may indicate a problem such as over-discharge, cell imbalance, or an internal short circuit.

On the other hand, unusually high voltage readings may indicate overcharging or thermal runaway within the battery. By carefully analysing and comparing voltage readings to known standards for lithium-ion batteries, you can identify potential faults and determine whether further investigation or action is required to resolve any potential problems found during testing.

Resistance Testing

Another important method of testing a faulty lithium-ion battery is resistance testing. To measure resistance, set the multimeter to resistance mode (ohms) and make sure the battery is disconnected from any circuits. Connect a lead from the multimeter to each terminal of the battery and record the resistance reading displayed on the screen.

Interpreting the resistance readings will allow you to accurately diagnose lithium-ion battery faults. Unusually high resistance readings may indicate internal damage or increased impedance due to aging or contamination of the battery.

Conversely, low resistance readings may indicate a short circuit or other form of internal electrical failure that requires immediate attention. By understanding how to properly interpret resistance readings in conjunction with other test results, you can gain insight into potential issues affecting the performance and safety rating of lithium-ion batteries, allowing you to intervene promptly before more serious problems arise.

Thermal Imaging for Detecting Hot Spots

In addition to traditional electrical testing, thermal imaging provides a non-contact method for detecting hot spots inside lithium-ion batteries, which are an important indicator of potential malfunctions such as overcharging, internal short-circuiting or battery degradation. Using a thermal imaging camera equipped with infrared technology, different areas of the battery are scanned while the battery is operating or charging. Thermal imaging is important because it can reveal temperature differences that may not be detected through visual inspection alone, and which could indicate critical issues affecting the health and safety of the battery.

The hot spots found by a thermal imaging camera can pinpoint specific areas that are experiencing abnormal heat and potential failure points that require immediate attention. To effectively use a thermal imaging camera to identify areas of overheating in lithium-ion batteries, ensure that the equipment is properly calibrated according to the manufacturer’s guidelines and systematically compare temperature variations in different parts of the battery pack – this is a proactive way of pre-empting serious failures before they escalate.

How can I extend battery life?

Battery Equipped Management System (BMS)

The Battery Management System (BMS) plays a critical role in monitoring the health and performance of lithium-ion batteries. A typical BMS consists of a variety of components such as voltage sensors, current sensors, temperature sensors, and control circuits that work together to ensure the safe operation and optimal efficiency of the battery pack.

The main functions of a BMS include monitoring individual cell voltages, balancing battery capacity during charging, preventing overcharging or overdischarging, and controlling temperatures within safe limits. Proper calibration of the BMS is critical to obtaining accurate readings and maximising the efficiency of the battery monitoring system.

Calibration involves setting reference points for voltage thresholds, current limits, temperature ranges and other parameters based on the specific characteristics of the lithium-ion cells used in the battery pack. By properly calibrating the BMS for each application, users can prevent premature battery aging or damage due to system misinterpretation or incorrect control operation.

Controlling Temperature to Optimise Battery Life

Temperature plays a critical role in the life and performance of lithium-ion batteries. The optimal temperature range for storing and using lithium-ion batteries is typically between 20°C and 25°C (68°F and 77°F).

Within this temperature range, the chemical reactions within the battery can occur most efficiently, ensuring maximum energy storage capacity and longest life. Lithium-ion batteries degrade at an accelerated rate when exposed to temperature extremes, such as below freezing or above 113°F (45°C).

Low temperatures thicken the electrolyte inside the battery, resulting in increased internal resistance and reduced performance. On the other hand, high temperatures accelerate the chemical reactions within the battery, leading to accelerated degradation over time.

To mitigate these effects, it is critical to keep devices containing lithium-ion batteries in a moderate temperature environment whenever possible. Protect your battery by avoiding prolonged exposure to direct sunlight or extreme cold.

Proper Charging Habits

To understand the impact of charging habits on the life of lithium-ion batteries, the concept of charging cycles is crucial. A charge cycle is defined as a complete discharge and charge of a battery.

Every time a battery undergoes a complete charge cycle, its capacity decreases slightly. Therefore, charging habits must be optimized to extend the life of lithium-ion batteries.

To maximize battery life, experts recommend avoiding frequent complete discharges and instead opting for partial discharges followed by recharging. Lithium-ion batteries prefer shallow discharge cycles to deep discharges, which can place an unnecessary burden on the battery.

Additionally, using a slow or trickle charge method is gentler on the battery than fast charging, which generates more heat during the charging process. By adopting these optimal charging habits, the lifespan of lithium-ion batteries can be greatly extended.

Conclusion

Monitoring the health of lithium-ion batteries is critical to maximising their life and performance. By paying attention to physical signs, performance indicators, temperature fluctuations, voltage output, number of cycles, as well as consulting the manufacturer’s guidelines and seeking professional advice when needed, you can ensure that your batteries are operating efficiently and safely. Remember, proper maintenance and proactive measures can significantly extend the life of your lithium-ion battery while minimising potential risks.

Let’s always remember that proactive maintenance of your equipment’s batteries not only ensures their optimal functionality, but also contributes to more sustainable methods of technology utilisation. By staying informed and taking appropriate action to maintain the health of lithium-ion batteries, we play a role in promoting a greener future by minimising e-waste through responsible consumption habits.

1 thought on “How to tell if a lithium ion battery is bad?”

Your article is a brilliant showcase of your ability to write with clarity and precision.