Introduction

In the realm of electrical systems, the measurement of battery frequency stands as a crucial pillar in ensuring optimal performance and longevity. Understanding battery frequency is akin to deciphering a hidden language that reveals the inner workings of energy storage devices.

Battery frequency serves as a key indicator of the health and functionality of batteries, offering valuable insights into their operational efficiency and state of charge. By delving into the intricacies of measuring battery frequency, we embark on a journey towards unlocking the mysteries that govern the realm of power storage.

Impact On Performance And Lifespan

The significance of measuring battery frequency extends far beyond mere numerical values on a display; it resonates deeply with the core functioning of energy storage systems. An understanding of how battery frequency influences performance and lifespan is akin to unraveling a symphony where each note contributes to the harmonious operation or gradual degradation of batteries over time. Fluctuations in battery frequency can signal underlying issues such as overcharging, undercharging, or internal resistance, all of which can have profound effects on both short-term performance and long-term durability.

Interplay Between Battery Frequency And System Efficiency

Battery frequency serves as a linchpin in the intricate machinery that powers modern technologies, from portable electronics to renewable energy systems. The impact of battery frequency reverberates throughout entire electrical setups, influencing not only individual components but also overall system efficiency. By grasping how battery frequency affects performance metrics such as voltage stability, charge/discharge cycles, and load handling capacity, we gain insights into optimizing energy utilization strategies for enhanced operational efficiency and prolonged system lifespan.

Understanding Battery Frequency

Definition Of Battery Frequency In The Context Of Electrical Systems

Battery frequency refers to the rate at which a battery’s voltage fluctuates or cycles within a given time period. In electrical systems, this frequency is measured in Hertz (Hz) and indicates how often the voltage output of a battery changes direction. A higher frequency means that the voltage fluctuates more rapidly, while a lower frequency signifies slower fluctuations.

This measurement is crucial for assessing the stability and health of a battery as it directly impacts its performance and efficiency. Moreover, battery frequency can also be understood as the oscillation pattern of the electrical signal produced by the battery.

It represents the repetitive nature of voltage variations over time, providing valuable insights into how consistently a battery delivers power. By monitoring and analyzing battery frequency, technicians can detect irregularities or abnormalities in voltage output, which may indicate potential issues such as internal resistance buildup or aging components within the battery.

Relationship Between Battery Frequency And Voltage Fluctuations

The relationship between battery frequency and voltage fluctuations is intricate yet significant in understanding the behavior of different types of batteries. Voltage fluctuations refer to variations in voltage levels that occur periodically due to internal factors such as chemical reactions or external influences like temperature changes.

These fluctuations directly influence the frequency at which batteries operate, impacting their overall stability and reliability. For instance, lead-acid batteries commonly exhibit lower frequencies compared to lithium-ion batteries due to differences in their internal chemistry and design.

Lead-acid batteries have slower voltage fluctuations resulting in lower frequencies, while lithium-ion batteries tend to have higher frequencies due to their rapid charge-discharge cycles. Understanding this relationship allows engineers and researchers to optimize battery performance by adjusting parameters like charging rates or temperature conditions to minimize excessive frequency variations that could harm battery longevity.

Types Of Batteries That Exhibit Frequency Variations

Various types of batteries exhibit distinct patterns of frequency variations based on their inherent characteristics and applications. For example, nickel-cadmium (NiCd) batteries typically display moderate-frequency oscillations due to their stable chemical composition but can experience sudden spikes under high load conditions.

On the other hand, nickel-metal hydride (NiMH) batteries demonstrate relatively smoother frequency curves with gradual transitions between charge-discharge cycles. Furthermore, advanced lithium-based batteries such as lithium-polymer (LiPo) or lithium iron phosphate (LiFePO4) exhibit high-frequency variations owing to their fast-charging capabilities and robust energy density.

These batteries are designed for quick power delivery with minimal energy loss, resulting in rapid oscillations in voltage levels corresponding to higher frequencies compared to traditional lead-acid counterparts. Understanding these distinctions among various battery types is fundamental for selecting suitable technologies based on specific requirements for applications ranging from consumer electronics to renewable energy systems.

Tools For Measuring Battery Frequency

Multimeters And Their Role In Measuring Battery Frequency

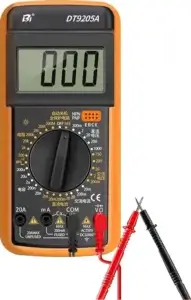

When it comes to measuring battery frequency, multimeters are one of the most commonly used tools due to their versatility and ease of use. A multimeter is a handheld device that combines several measurement functions in one unit, including voltage, current, and resistance measurements.

To measure battery frequency using a multimeter, you simply need to switch the device to the frequency measurement mode, typically denoted by the symbol “Hz.” Once in this mode, connect the multimeter probes to the positive and negative terminals of the battery and read the displayed frequency value on the screen. Multimeters provide a quick and convenient way to monitor battery frequency in various applications.

Oscilloscopes As A More Advanced Tool For Precise Frequency Measurement

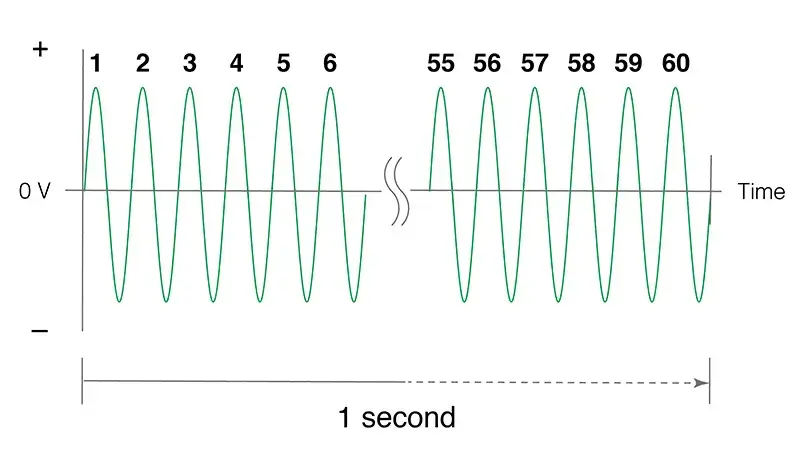

For more advanced and precise frequency measurement of batteries, oscilloscopes come into play. An oscilloscope is a sophisticated instrument that displays voltage signals as waveforms on a screen. When measuring battery frequency with an oscilloscope, you can capture detailed waveform patterns that allow for accurate analysis of frequency variations.

By connecting the oscilloscope probes to the battery terminals, you can observe the voltage fluctuations over time and determine the exact frequency with high precision. Oscilloscopes are favored for their ability to visualize complex signals and provide detailed insights into battery performance.

Portable Handheld Devices For On-The-Go Frequency Monitoring

In scenarios where mobility is essential or when conducting fieldwork, portable handheld devices offer a convenient solution for on-the-go frequency monitoring of batteries. These compact devices are designed for portability without compromising accuracy, making them ideal for technicians working in diverse environments.

Portable handheld devices often come equipped with LCD screens that display real-time frequency readings directly from the batteries being tested. With features such as data logging capabilities and customizable settings, these devices enable users to track battery frequencies efficiently while on-site or during troubleshooting tasks.

Setting Up The Multimeter For Frequency Measurement Mode

To accurately measure battery frequency using a multimeter, the first crucial step is to ensure that the multimeter is set to the appropriate frequency measurement mode. Most modern digital multimeters come equipped with a frequency measurement function, often denoted by the symbol “Hz.” This setting allows the multimeter to detect and display the frequency of an alternating current (AC) signal accurately. To access this mode, turn on the multimeter and navigate through its settings until you reach the frequency measurement option.

Once you have selected the frequency measurement mode on your multimeter, it is essential to set the range appropriately to match the expected frequency range of your battery. Choosing an incorrect range can result in inaccurate readings or even damage to the multimeter.

Refer to your battery specifications or conduct prior research to determine an estimated range of frequencies that your battery operates within. Adjusting the range ensures that the multimeter can capture and display frequency values within that specific range with precision.

Connecting The Multimeter Probes To Battery Terminals

After setting up your multimeter for frequency measurement, it is time to connect its probes to the battery terminals correctly. Begin by identifying which terminal of your battery corresponds to positive (+) and negative (-) connections. In most cases, red probes are used for positive terminals while black probes are used for negative terminals.

Ensure that both probes are securely connected without any loose or faulty attachments as this can lead to inaccurate readings. When attaching the probes, take caution not to create any short circuits between them or inadvertently touch other components nearby.

Make sure that there is no residual voltage present in either probe before making contact with the battery terminals as this could affect measurements. Once both probes are firmly connected, observe any displayed readings on your multimeter’s screen – this indicates successful communication between your device and battery.

Reading And Interpreting Displayed Frequency Value

With proper setup and probe connection completed, you can now read and interpret the displayed frequency value on your multimeter. The value displayed represents how many cycles per second (Hz) occur within your battery’s electrical system – essentially indicating how rapidly electricity alternates directions within it.

Take note of any fluctuations or steady patterns in these values as they may provide insights into your battery’s health and performance over time. Analyzing these frequency readings alongside other diagnostic metrics can help identify potential issues such as irregular charging patterns or abnormal power output levels from a battery system.

Calibrating Oscilloscope Settings For Precise Readings

When it comes to measuring battery frequency with an oscilloscope, precise calibration of the settings is crucial for obtaining accurate readings. Start by adjusting the vertical and horizontal scales to ensure that the waveform displayed on the screen is properly scaled.

Fine-tune the time base settings to capture multiple complete cycles of the battery frequency waveform for a more comprehensive analysis. Additionally, adjusting the trigger level will help stabilize the waveform on the display, making it easier to measure specific frequencies accurately.

To calibrate the oscilloscope for precise frequency measurements, set the probe attenuation factor correctly based on your specific measurement setup. This ensures that voltage levels are accurately represented on the display.

Pay close attention to the input impedance settings of the oscilloscope as mismatched impedance can lead to signal distortion and inaccurate frequency readings. By carefully calibrating these settings, you can enhance the precision and reliability of your battery frequency measurements using an oscilloscope.

Utilizing Spectrum Analyzers For Detailed Analysis Of Harmonic Frequencies

For a more in-depth analysis of battery frequency and its associated harmonics, utilizing spectrum analyzers proves invaluable. These sophisticated instruments break down complex waveforms into their individual frequency components, allowing you to identify and measure harmonic frequencies with precision.

Spectrum analyzers provide a detailed graphical representation of frequency content over a wide range, enabling you to spot irregularities or distortions in the battery’s output signal. When using a spectrum analyzer for analyzing harmonic frequencies in batteries, consider adjusting parameters such as resolution bandwidth and sweep time to optimize the clarity and accuracy of your measurements.

By selecting appropriate settings tailored to your specific measurement requirements, you can isolate individual harmonics effectively and gain insights into potential issues like resonance or interference within the battery system. The detailed spectral information provided by spectrum analyzers empowers you to diagnose complex frequency phenomena and make informed decisions regarding battery performance optimization.

Unlocking Hidden Insights: Delving Deeper Into Harmonic Frequencies

Beyond just measuring fundamental frequencies, exploring harmonic frequencies through spectrum analysis reveals hidden insights into battery behavior that may otherwise go unnoticed. By examining harmonics – integer multiples of the fundamental frequency – you can uncover patterns or anomalies that indicate underlying issues affecting battery performance or efficiency.

Identifying dominant harmonic components and their amplitudes provides a comprehensive view of how various frequencies interact within the system. Furthermore, analyzing harmonic frequencies using spectrum analyzers enables proactive maintenance strategies by detecting early signs of degradation or abnormalities in battery operation.

By monitoring harmonic content over time, you can track changes in frequency profiles and anticipate potential failure modes before they escalate into critical issues. This proactive approach based on detailed harmonic analysis not only enhances reliability but also prolongs battery lifespan through timely intervention and mitigation strategies based on data-driven insights.

Addressing Interference And Noise During Measurement

One common challenge when measuring battery frequency is dealing with interference and noise that can affect the accuracy of the readings. Interference can be caused by external factors such as electromagnetic fields or other electrical devices operating nearby. To address this issue, it is important to ensure that the measuring environment is shielded from external interference sources.

Using shielded cables and keeping a safe distance from other electronic devices can help minimize interference during measurement. Moreover, utilizing signal filters or noise reduction techniques can also help mitigate the impact of unwanted noise on frequency measurements.

Filters can be applied either at the measurement device level or through software processing to remove unwanted signals and enhance the precision of frequency readings. By carefully selecting appropriate filtering settings and calibrating the equipment accordingly, one can effectively overcome issues related to interference and noise in battery frequency measurement.

Resolving Inaccuracies Due To Improper Probe Placement

Improper probe placement is another common source of inaccuracies in battery frequency measurement. Placing the probes incorrectly or making poor contact with the battery terminals can lead to erroneous readings and hinder the reliability of frequency measurements.

To resolve this issue, it is essential to ensure that the probes are securely connected to the appropriate terminals with a stable connection. Proper probe placement involves making direct contact with the terminal points while avoiding any potential obstructions or contaminants that could interfere with the measurement process.

Additionally, regularly inspecting and cleaning the probes for any dirt or damage is crucial for maintaining accurate measurements. By paying attention to probe placement techniques and ensuring a secure connection with minimal impedance, one can effectively eliminate inaccuracies linked to improper probe positioning during battery frequency measurement.

Applications Of Battery Frequency Measurement

In Automotive Industry: Monitoring Alternator Output Frequencies

One crucial application of battery frequency measurement lies in the automotive industry, where monitoring alternator output frequencies is essential for ensuring proper functioning of vehicles. Alternators are responsible for converting mechanical energy into electrical energy to charge the vehicle’s battery and power various electrical systems.

By measuring the frequency of the alternator output, technicians can assess its performance and detect any irregularities that may indicate potential issues. Tracking alternator output frequencies allows automotive professionals to troubleshoot charging system problems effectively.

Fluctuations in frequency can point towards issues such as a faulty voltage regulator, worn-out brushes, or belt slippage affecting the alternator’s efficiency. Timely detection of these issues through frequency measurements helps prevent unexpected breakdowns and ensures optimal performance of the vehicle’s electrical system.

Moreover, continuous monitoring of alternator frequencies enables proactive maintenance practices in the automotive industry. By establishing baseline frequency values for different vehicle models, technicians can set up regular checks to identify deviations early on and take preventive measures to avoid costly repairs down the line.

In Renewable Energy Systems: Tracking Solar Panel Inverter Frequencies

The utilization of battery frequency measurement extends beyond automobiles into renewable energy systems, particularly in tracking solar panel inverter frequencies. In solar power installations, inverters play a vital role by converting direct current (DC) electricity generated by solar panels into alternating current (AC) suitable for powering residential or commercial applications.

Monitoring the frequency of these inverters is crucial for ensuring efficient energy conversion and grid compatibility. By measuring the frequency output of solar panel inverters, energy technicians can assess system performance and address any deviations promptly.

Variations in inverter frequencies could indicate issues like overloading, grid instability, or component failure within the solar power system. Analyzing these frequency changes allows operators to optimize energy production and maintain grid stability for reliable power supply.

Frequent monitoring and analysis of solar panel inverter frequencies also support predictive maintenance strategies in renewable energy systems. Identifying abnormal frequency patterns early on enables operators to schedule maintenance activities proactively, replace malfunctioning components before they fail completely, and maximize overall system efficiency and longevity.

Conclusion

Summary Of Key Points Discussed

In this comprehensive article, we delved into the intricate world of Lithium Battery frequency measurement. We explored the fundamental concepts of battery frequency, its significance in determining electrical performance, and various tools and techniques used for accurate measurement.

From understanding the relationship between battery frequency and voltage fluctuations to exploring advanced methods with oscilloscopes and spectrum analyzers, we have provided a thorough guide for enthusiasts and professionals alike. Troubleshooting common issues and discussing real-world applications have further enriched our exploration.

Importance Of Regular Battery Frequency Measurements For Optimal Performance

Regularly measuring battery frequency is not just a technical task; it is a crucial maintenance practice that can significantly impact the performance and longevity of batteries. By monitoring frequency variations, one can detect early signs of potential problems such as deteriorating battery health or issues with charging systems.

Timely interventions based on accurate frequency measurements can prevent costly breakdowns, optimize energy efficiency, and ensure uninterrupted power supply in critical applications. In embracing the practice of regular battery frequency measurements, we empower ourselves to stay proactive in maintaining our electrical systems at their peak efficiency.

By being vigilant about monitoring these often-overlooked metrics, we take proactive steps towards ensuring reliable operation and extending the lifespan of our batteries. Remember, knowledge is power – and in this case, it’s the power to keep your electrical systems running smoothly.

1 thought on “Measuring Battery Frequency: A Comprehensive Guide”

Hi Rob,To your concerns, the recommended cycle of LiFePO4 battery is 10 to 90 SOC.5 to 95 will also be fine.For storage, yes, it is recomended to keep at 50 SOC.Some of the battery meter is voltage meter, which is based on the battery voltage, not accurate.Columb meter which is based on the current and calculation by time & current, is more accurate.Andy