Introduction

The world of batteries is a fascinating realm that powers countless devices and technologies we rely on daily. Within this landscape, two terms frequently arise: OEM and ODM batteries.

Understanding the nuances between these types of batteries is crucial for businesses and consumers seeking the right power solutions for their needs. In this article, we will delve into the intricate world of OEM and ODM batteries, exploring their definitions, implications in various industries, and key differences.

Definition of OEM and ODM Batteries

OEM (Original Equipment Manufacturer) batteries are those produced by a company that designs and manufactures products using their own brand name. These batteries are typically tailored to specific devices or equipment, ensuring optimal compatibility and performance. On the other hand, ODM (Original Design Manufacturer) batteries are manufactured based on specifications provided by another company but sold under the buyer’s brand name.

In today’s market saturated with electronic gadgets, industrial machinery, electric vehicles, and renewable energy systems, the demand for high-quality OEM and ODM batteries has skyrocketed. These power sources serve as the lifeblood of modern technology-driven industries, powering everything from smartphones to electric cars to grid-scale energy storage systems.

Importance of Batteries in Various Industries

Batteries play a pivotal role in an array of industries due to their ability to store electricity efficiently for later use. In consumer electronics, such as smartphones and laptops, reliable battery performance directly impacts user experience—dictating how long a device can operate without needing a recharge. Similarly, in sectors like healthcare where medical devices rely on uninterrupted power supply for patient care or manufacturing plants dependent on backup power systems during outages—batteries are indispensable components.

Moreover, as society embraces sustainable practices and transitions towards renewable energy sources like solar panels or wind turbines—an increased focus on energy storage solutions emerges. Large-scale battery installations facilitate storing excess energy generated during peak production times for later use when demand exceeds supply—a critical function supporting clean energy initiatives worldwide.

Overview of the Differences Between OEM and ODM Batteries

While both OEM and ODM batteries serve as vital energy storage solutions across diverse industries—key differentiators exist between these two categories. OEM batteries offer customized solutions specifically designed to meet the requirements of original equipment manufacturers’ products—ensuring seamless integration and optimal performance within designated devices. On the contrary, ODM battery suppliers cater to clients seeking ready-made battery designs that can be rebranded under their own label—providing cost-effective options without sacrificing quality or reliability.

Understanding these fundamental distinctions is essential when selecting battery solutions tailored to unique business needs or consumer preferences. Whether prioritizing brand consistency with OEM offerings or exploring versatile design options with ODM alternatives—the choice between these battery types profoundly influences product performance standards across various sectors.

OEM Batteries

Definition and Characteristics

OEM batteries, short for Original Equipment Manufacturer batteries, are produced by a company that designs and manufactures products based on their own specifications. In the realm of batteries, OEM manufacturers create custom battery solutions tailored to specific requirements of different industries.

These batteries are typically designed to fit seamlessly into the original equipment without any modifications needed, ensuring compatibility and optimal performance. When it comes to characteristics, OEM batteries stand out for their precision engineering and high-quality components.

They are built with meticulous attention to detail, using advanced technologies and materials to meet the demanding standards set by the original equipment manufacturer. Whether it’s a lithium-ion battery for a medical device or a lead-acid battery for industrial machinery, OEM batteries are known for their reliability and efficiency in powering various types of equipment.

Pros of OEM Batteries

One of the key advantages of OEM batteries is the assurance of quality they provide. By sourcing batteries directly from the original equipment manufacturer, businesses can be confident in the reliability and performance of these batteries.

Quality assurance measures ensure that each OEM battery undergoes rigorous testing processes to meet stringent standards before being supplied to customers. Brand consistency is another significant advantage offered by OEM batteries.

The use of genuine OEM batteries helps maintain uniformity in terms of performance and safety across all devices or equipment within a particular brand’s ecosystem. This consistency not only enhances user experience but also contributes to brand loyalty and trust among consumers who rely on these products.

Customization Options

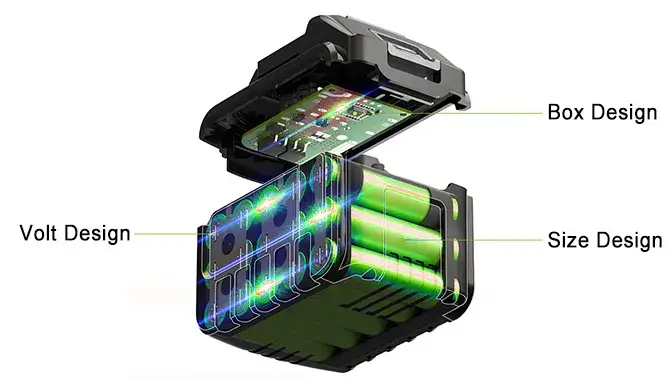

OEM batteries offer customization options that allow businesses to tailor battery solutions according to their specific needs. From capacity and size specifications to voltage requirements and cycle life considerations, OEM manufacturers work closely with clients to develop bespoke battery solutions that align with their unique applications. This level of customization ensures that businesses can optimize battery performance while meeting specific operational demands.

Examples of industries using OEM batteries span a wide range of Industries including Healthcare (Wheelchair Batteries, Hearing Aid Batteries), Automotive (Starter Batteries, High Rate Batteries), Marine (Marine ESS, Electric Outboard Motor), Telecommunications (Mobile Devices), Industrial (AGV Battery, Lithium Forklift Battery, Floor Sweeper Battery, Scissor Lift Battery) Aerospace (Drones), Energy Storage (C&I ESS, Home Battery Backup), and many more. Each industry benefits from the tailored solutions provided by OEM battery manufacturers in enhancing product performance, reliability, and overall user experience.

ODM Batteries

Definition and Features

In the realm of battery manufacturing, ODM (Original Design Manufacturer) batteries represent a unique approach where a company designs and manufactures batteries based on the specifications provided by another brand or company. ODM batteries are tailored to meet specific requirements, offering a high level of customization in terms of size, capacity, and performance. These batteries are designed to seamlessly integrate into the products of the brand they are manufactured for, ensuring compatibility and optimal functionality.

Pros of ODM Batteries

The utilization of ODM batteries offers several notable advantages to businesses across various industries. One significant advantage is cost-effectiveness.

By opting for ODM battery solutions, companies can save on development costs associated with designing their own batteries from scratch. This cost-efficient approach allows businesses to allocate resources more strategically, focusing on other aspects of product development or innovation.

Cost-Effectiveness: A Strategic Business Approach

Moreover, ODM batteries contribute to time efficiency in product development cycles. With pre-existing battery designs that can be customized according to specific requirements, companies can accelerate their time-to-market significantly. This agility in adapting existing battery solutions saves valuable time during the production phase and enables faster product launches.

Flexibility in Design: Tailoring Batteries to Unique Specifications

Another key advantage of ODM batteries lies in the flexibility they offer in design customization. Companies can work closely with manufacturers to tailor the battery specifications precisely to their needs, whether it involves adjusting capacity for longer runtime or enhancing safety features for specialized applications. This adaptability ensures that products featuring ODM batteries align perfectly with the brand’s identity and performance standards.

Examples of Industries Utilizing ODM Battery Solutions

Various industries benefit from leveraging ODM battery solutions tailored to their specific requirements. For instance, the consumer electronics sector often relies on ODM batteries for smartphones, laptops, and wearables due to their ability to be customized according to device size constraints and power demands.

Additionally, industries such as automotive manufacturing utilize ODM batteries for electric vehicles (EVs) where design flexibility is crucial for optimizing energy storage capacity within limited space constraints. Overall, the adoption of ODM battery solutions empowers businesses across diverse sectors with cost-effective, efficient, and customizable energy storage options that align seamlessly with their product development strategies and market demands.

Comparing OEM and ODM Batteries: Unveiling the Performance Metrics

Capacity: The Power Within

When it comes to battery capacity, OEM and ODM batteries differ in their specifications. OEM batteries are known for their consistent and reliable performance, offering a predetermined capacity based on the manufacturer’s specifications.

On the other hand, ODM batteries may provide varying capacities depending on the customization requirements of the client. While OEM batteries offer standardized capacity levels, ODM batteries can be tailored to meet specific power needs, allowing for a more flexible approach in addressing diverse energy demands.

Lifespan: Endurance Tested

In terms of lifespan, OEM batteries are designed to meet stringent quality standards set by the original equipment manufacturer. These batteries undergo rigorous testing procedures to ensure longevity and durability over an extended period.

Conversely, ODM batteries may vary in lifespan depending on the components used and manufacturing processes employed by different suppliers. While some ODM batteries may offer comparable lifespan to OEM counterparts, others may exhibit shorter durability due to variations in production quality and materials used.

Charging Time: Efficiency Matters

Charging time is a critical factor when evaluating battery performance. OEM batteries are engineered for optimal charging efficiency, providing quick and reliable power replenishment within specified timeframes.

On the contrary, ODM batteries may exhibit differences in charging time based on design variations and manufacturing techniques employed by different suppliers. While some ODM batteries may offer rapid charging capabilities similar to OEM models, others might have longer charging durations due to differences in technology implementation and quality control measures.

The Future of OEM and ODM Battery Technology

Emerging Trends in Battery Manufacturing

The future of OEM and ODM battery technology is poised for exciting advancements, especially in the realm of battery manufacturing. One emerging trend is the shift towards solid-state batteries, which promise higher energy densities, faster charging times, and improved safety compared to traditional lithium-ion batteries. Manufacturers are investing heavily in research and development to overcome current limitations and bring solid-state batteries to mass production.

Another key trend is the integration of artificial intelligence (AI) and machine learning algorithms in battery manufacturing processes. By leveraging AI-driven predictive maintenance and quality control systems, manufacturers can optimize production efficiency, reduce waste, and ensure consistent battery performance.

This cutting-edge approach not only enhances productivity but also enables real-time monitoring to detect potential issues before they escalate. Furthermore, 3D printing technology is revolutionizing battery design and production methods.

Additive manufacturing allows for intricate geometric structures that optimize energy storage capacity while minimizing weight and size constraints. This customization capability opens up a new era of tailored battery solutions for diverse applications ranging from consumer electronics to electric vehicles.

Sustainability Initiatives in the Battery Industry

As the global focus on sustainability intensifies, the battery industry is increasingly adopting eco-friendly practices to minimize environmental impact. One significant initiative involves developing recyclable and reusable materials for battery components.

By utilizing recycled metals like lithium, cobalt, and nickel in manufacturing processes, OEMs and ODMs can reduce reliance on virgin resources while promoting a circular economy model. Moreover, Keheng companies are exploring innovative ways to extend battery lifespan through enhanced durability and performance optimization strategies.

This includes implementing smart charging algorithms that prolong battery health by preventing overcharging or deep discharging cycles. By prioritizing longevity over rapid obsolescence, manufacturers contribute to reducing e-waste generation while ensuring sustainable product life cycles.

The synergy between sustainable power generation sources and advanced battery technologies paves the way for a more resilient and environmentally conscious future. By embracing these emerging trends in both manufacturing processes and sustainability initiatives, OEMs and ODMs are driving forward the evolution of battery technology towards a more efficient, reliable, and environmentally responsible future.

Conclusion

Summary of Key Points on OEM and ODM Batteries

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) batteries play pivotal roles in various industries by providing power solutions tailored to specific needs. OEM batteries offer unparalleled quality assurance, brand consistency, and customization options, making them ideal for brands looking to maintain their reputation. On the other hand, ODM batteries are valued for their cost-effectiveness, time efficiency, and flexibility in design, catering to businesses seeking efficient and customizable power solutions.

Impact on Various Industries

The impact of OEM and ODM batteries transcends industries such as automotive, consumer electronics, healthcare devices, and renewable energy systems. These batteries not only power devices but also influence product performance, reliability, and overall user experience. By utilizing OEM or ODM battery solutions, industries can enhance their products’ competitiveness in the market while meeting the evolving demands of consumers who seek sustainable and innovative technologies.

Future Prospects for Battery Technology

Looking ahead, the future of battery technology holds promise for advancements in energy storage capacity, efficiency improvements, and sustainable manufacturing practices. With a growing emphasis on environmental sustainability and technological innovation, researchers are exploring new materials and designs to create batteries that are not only powerful but also eco-friendly. The evolution of OEM and ODM battery technology is set to drive progress in energy storage solutions across industries while contributing to a greener future powered by cutting-edge technologies.