Technology is also progressing in the development era, and now the application of batteries has been extended to our side or body. Like electric cars, lights, or laptops, mobile phones, to small wireless headphones, hearing aids, etc.

Since Keheng new energy battery manufacturers have their own battery cell production bases, we can eliminate a bunch of cumbersome battery cell production processes, thereby reducing the workload and increasing product quality control.

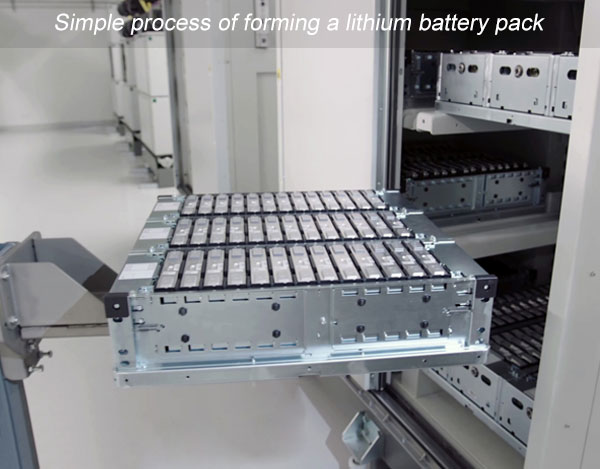

Among them, each production workshop also has a set of independent operating procedures, taking the small battery pack workshop as an example.

Check the incoming material first. The inspection of incoming materials includes inspection of materials, accessories, appearance of batteries, tools, etc., mainly to prevent omissions, leakages, and bad batteries from appearing again during subsequent processing operations.

After the inspection, the battery cells are tested for charging, capacity distribution, and formation. There are a few things to pay attention to when charging the lithium battery, one is the voltage setting of the charging cabinet, the other is whether the battery direction is reversed, and the third is whether the digital display of the charging cabinet panel is correct. Failure to do any of the above steps will damage the battery.

After a series of tests are completed, someone will collect the cells and send them to the automatic sorting machine to sort the quality of the cells. High-quality cells will be selected, and various styles of welding combinations, protection plates, fixing frames or various terminals will be added according to customer requirements.

After the battery is assembled, it will be sent to the next station. Since the battery is in a semi-naked state during the operation, our workers will uniformly cover the assembled battery with a layer of PVC. The purpose of this is to improve the safety of the battery when using it, to better protect the battery cell, and to put on a neat and beautiful coat for the battery core.

Sometimes it will be replaced with the PVC specified by the customer for packaging. After the PVC is stripped, the battery pack will be printed and printed, such as model, mAh, capacity, brand name and so on.

After the coding is completed, the final inspection and shipment inspection will be carried out. Shipping inspection is to reduce product quality problems, incorrect processing, and appearance inconsistencies.

After the above processes are completed, the final step is to pack, seal, and ship.

The battery pack is used in solar street lamps for power supply. Don’t look at him as just a small battery, the capacity after parallel connection reaches 10,000 mAh.

Keheng New Energy’s Range Of Products

- 100AH 12V Low Temperature Heating Enable

- Lithium Battery Cell

- Lithium Battery Pack

- Escooter/Ebike Battery

- 12V/24V Lifepo4 Battery

- Portable Power Station

- ESS Energy Storagy Systems

- Deep Cycle Batteries With BMS

- Low Temperature 24V 60AH Battery